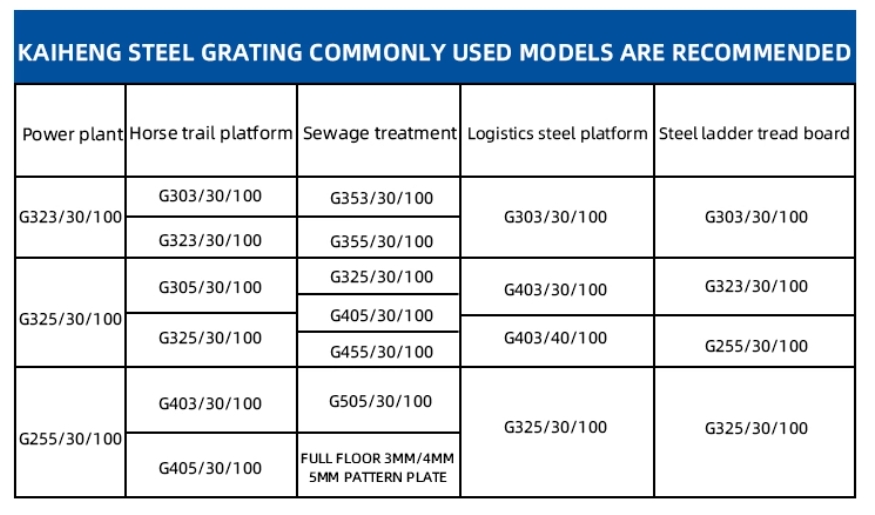

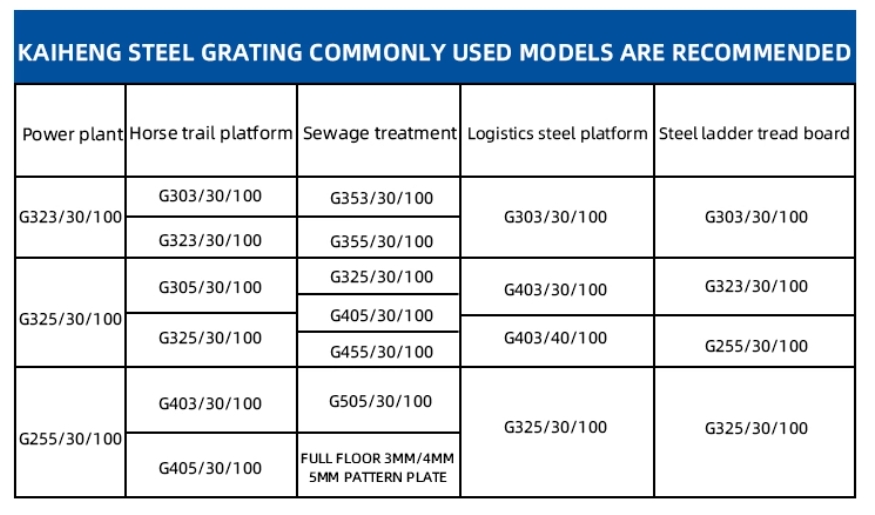

Introduction Of Steel Grating

Product Overview

Durable Steel Grating Metal Driveway Grates Galvanized Steel Grating is a robust grating solution designed specifically for driveway applications. Constructed with heavy-gauge bearing bars made from high-quality steel that undergoes rigorous material testing and staggered crossbar placement engineered for optimal load distribution, it withstands continuous pressure from vehicles ranging from compact cars weighing around 1.5 tons to 5-ton delivery trucks. The galvanized surface treatment, which includes a pre-treatment process of degreasing and pickling to ensure clean steel surfaces, ensures resilience against road salts used in winter, heavy rain with high acidity, and prolonged UV exposure in sunny climates, making it suitable for both residential and commercial driveway installations in diverse climatic zones, from cold northern regions to humid southern areas.

Product Specifications

Parameter | Details |

Material | High-quality low-carbon steel (Q235A) with good ductility to absorb impact from vehicle tires |

Length | 3m - 8m (customizable with 1m increments to fit driveway lengths of various sizes) |

Width | 1m - 2m to accommodate different driveway widths, including single and double car driveways |

Thickness of bearing bar | 8mm - 15mm to handle the weight of different vehicle types |

Galvanized layer thickness | ≥90μm (with passivation treatment to enhance corrosion resistance, forming a protective film on the zinc layer) |

Load capacity | ≥3000kg/m² (certified for H-20 highway load standards, ensuring it can bear heavy commercial vehicles) |

Features

Exceptional Durability

Manufactured with normalized steel that undergoes heat treatment at 900-950°C followed by slow cooling to reduce internal stress, it resists deformation even after 100,000+ vehicle passes, which is equivalent to approximately 20 years of average residential driveway usage. The welded joints are reinforced with fillet welds of 5mm minimum leg length, eliminating loosening under repeated impact from tire pressure, ensuring long-term structural stability.

Superior Anti-slip Performance

Surface serrations with 3mm depth and 5mm spacing, designed through extensive testing to maximize friction, create friction coefficients exceeding 0.8 (dry conditions) and 0.6 (wet conditions), exceeding ASTM F1677 safety standards for pedestrian walkways and vehicle surfaces. This significantly reduces the risk of vehicles skidding, especially during rainy or snowy weather, enhancing driveway safety.

Good Drainage & Debris Management

45% open area ratio, calculated based on the total area of the grating, allows 100L/min/m² water flow, which is sufficient to handle heavy rainfall of up to 50mm per hour, preventing puddles during heavy rain. The 20mm crossbar spacing blocks large debris such as stones and branches while allowing small particles like sand to pass through, reducing clogging risks and minimizing the need for frequent cleaning.

Application

It is extensively applied in private residences (residential driveways leading to garages, garage entrances with high vehicle turnover), commercial properties (retail parking lot driveways with constant customer vehicle flow, hotel valet areas where cars are parked and retrieved frequently), and industrial parks (warehouse loading docks with delivery trucks coming and going, truck terminals with heavy vehicle traffic). The grating protects underlying concrete from vehicle impact, which can cause cracks and damage over time, reduces frost heave damage in cold climates by allowing water to drain and preventing ice formation under the grating, and facilitates drainage in low-lying areas prone to flooding, ensuring driveways remain usable in various weather conditions.

Custom Service

Customization options include variable bar spacing (100mm/150mm/200mm) to accommodate different vehicle types, from small cars to larger trucks with wider tires, edge banding with a thickness of 3mm for safety to prevent tripping hazards, and pre-drilled anchor holes with a diameter of 12mm for specific foundation systems such as concrete or asphalt. We provide free site measurement guidance with professional technicians visiting the site to take accurate dimensions and installation blueprints with detailed step-by-step instructions for large projects, ensuring seamless installation.

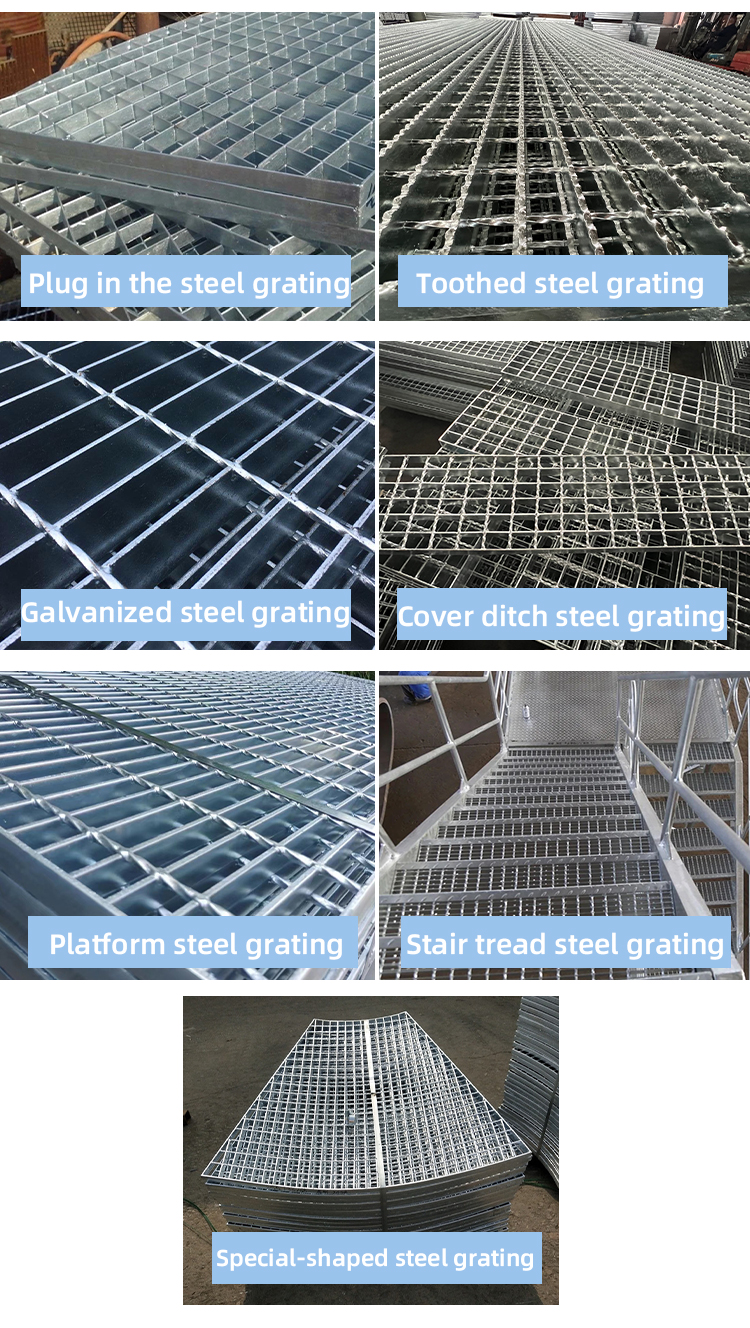

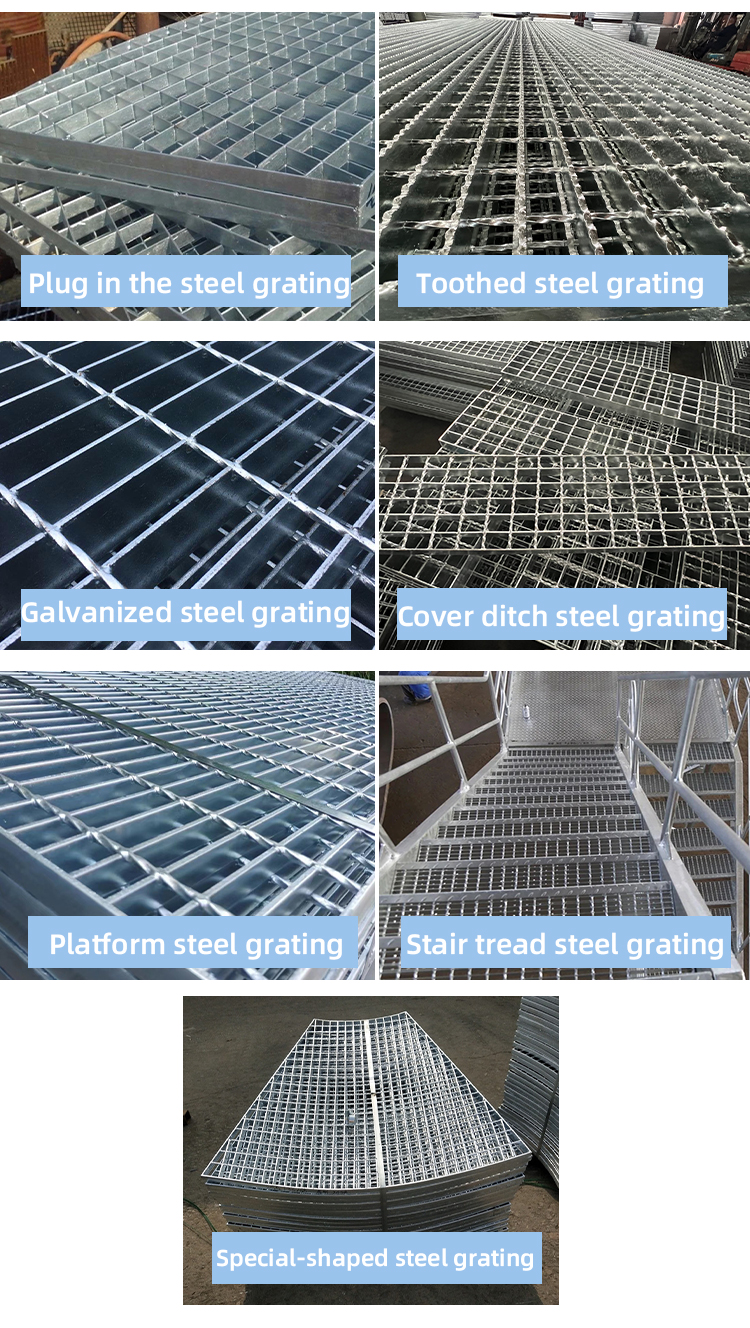

Kinds Of Steel Grating

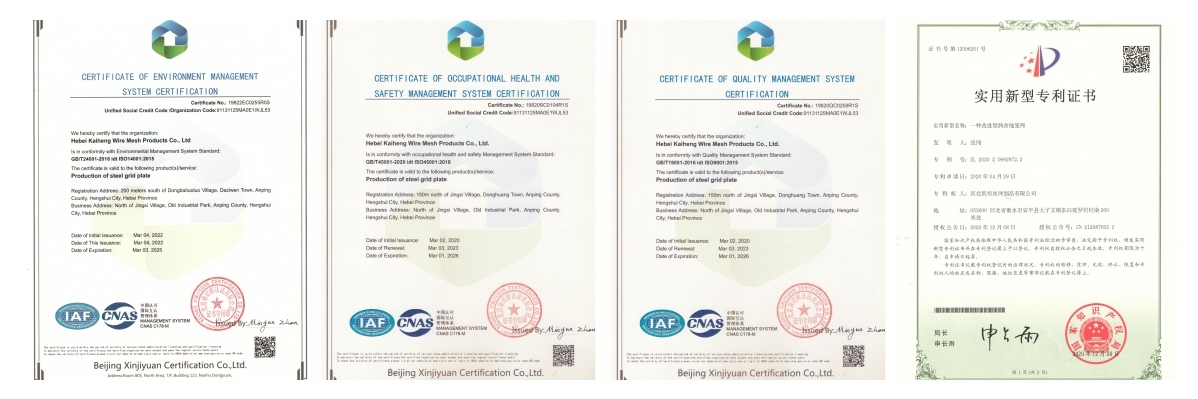

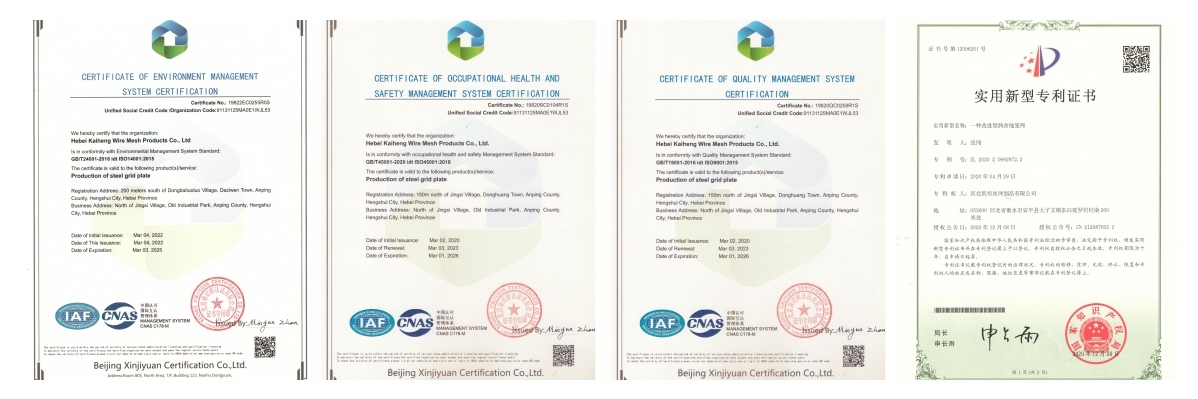

OUR CERTIFICATE

Our Factory Production

Hebei Kaiheng Wire Mesh Products Co. Ltd. is a leading manufacturer of steel grating platesproducing over 3000 plates daily and holding multiple quality certifications, focusing on industriessuch as petrochemical and hydropower.

With a high-end intelligent industrial park integrating production and research and developmentand two patent information items, Kaiheng specializes in the steel grating series and offerscustomized solutions tailored to meet the needs of various customers.