Introduction Of Steel Grating

Product Overview

Galvanized Steel Grating Insert Steel Grid Bar Grating Plate is a versatile grating product featuring an innovative insert-locking design that sets it apart from traditional grating solutions. Unlike traditional welded gratings, its precision-machined bearing bars, manufactured using CNC machines for high accuracy, feature slots that interlock with crossbars, creating a mechanical connection that enhances load distribution by up to 30% compared to welded alternatives. This unique structure makes it suitable for applications requiring frequent disassembly, such as temporary platforms used in construction projects and modular structures that need to be reconfigured based on changing needs.

Product Specifications

Parameter | Details |

Material | Mild steel (S235JR) with a yield strength of 235MPa, providing good formability for the insert slots |

Length | 2m - 6m (customizable to fit various project sizes and requirements) |

Width | 0.6m - 1.2m for flexible use in different applications with limited space |

Thickness of bearing bar | 6mm - 10mm to balance strength and weight for easy handling |

Galvanized layer thickness | ≥80μm to provide adequate corrosion resistance in indoor and outdoor environments |

Load capacity | ≥800kg/m² to support the weight of workers and light equipment |

Features

Stable Interlocking Structure

The insert design creates 360° contact between bearing bars and crossbars, which significantly increases shear resistance by 30% compared to welded gratings. This mechanical lock is achieved through precise slot dimensions that ensure a tight fit, preventing loosening during vibration, which is common in equipment platforms near pumps or generators. The stable structure also minimizes noise and movement, providing a secure working surface.

Tool-free Installation & Reusability

No welding required—grating panels can be assembled/disassembled using simple hand tools such as wrenches, reducing installation time by 50% compared to welded gratings. The reusable design allows for easy relocation during facility renovations or expansions, making it a cost-effective solution for projects with changing requirements. This also reduces waste, making it an environmentally friendly option.

Uniform Load Distribution

Precision-engineered slot dimensions with a tolerance of ±0.1mm ensure consistent pressure distribution across all contact points, minimizing stress concentrations that can lead to premature failure. This uniform load distribution extends service life in dynamic load environments where the load changes frequently, such as in areas with moving equipment or varying numbers of workers.

Application

This grating is commonly used in construction projects (temporary scaffolding platforms for workers to stand and work, formwork supports that need to be adjusted as the concrete sets), industrial facilities (machine access platforms where technicians need to reach equipment for maintenance, conveyor walkways alongside production lines), and commercial buildings (retail mezzanines used for storage or additional retail space, exhibition hall floors that need to be reconfigured for different events). It excels in applications requiring periodic access to underlying systems, such as cable trays for electrical wiring or plumbing lines that need regular inspection and maintenance, as it can be easily removed and reinstalled without damaging the grating or the underlying systems.

Custom Service

We offer custom insert profiles (rectangular/square) with different dimensions to meet specific load requirements and installation needs. Bar spacing options can be adjusted from 50mm to 150mm to accommodate different application scenarios. Special finishes like powder coating with a thickness of 60-80μm or epoxy painting that provides chemical resistance are available for enhanced chemical resistance in pharmaceutical or food processing facilities where hygiene and corrosion resistance are critical. Our technical team can also provide advice on the best insert design and specifications based on the customer's specific application.

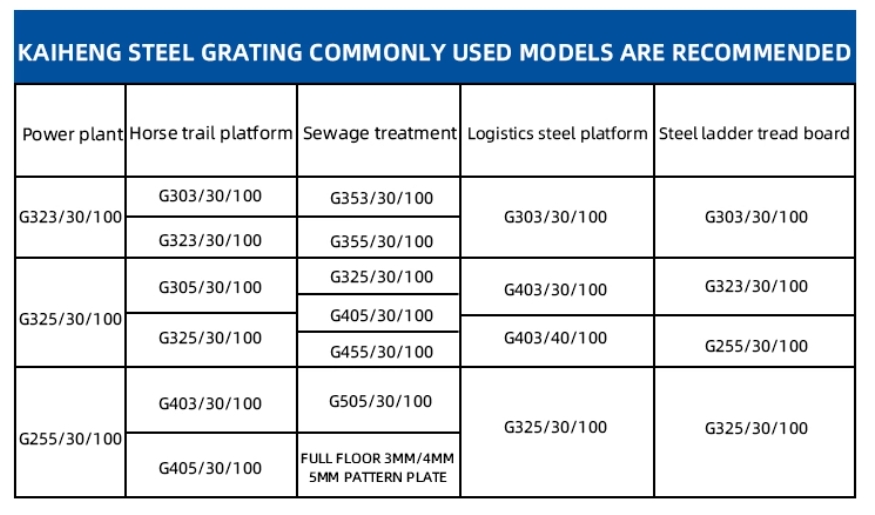

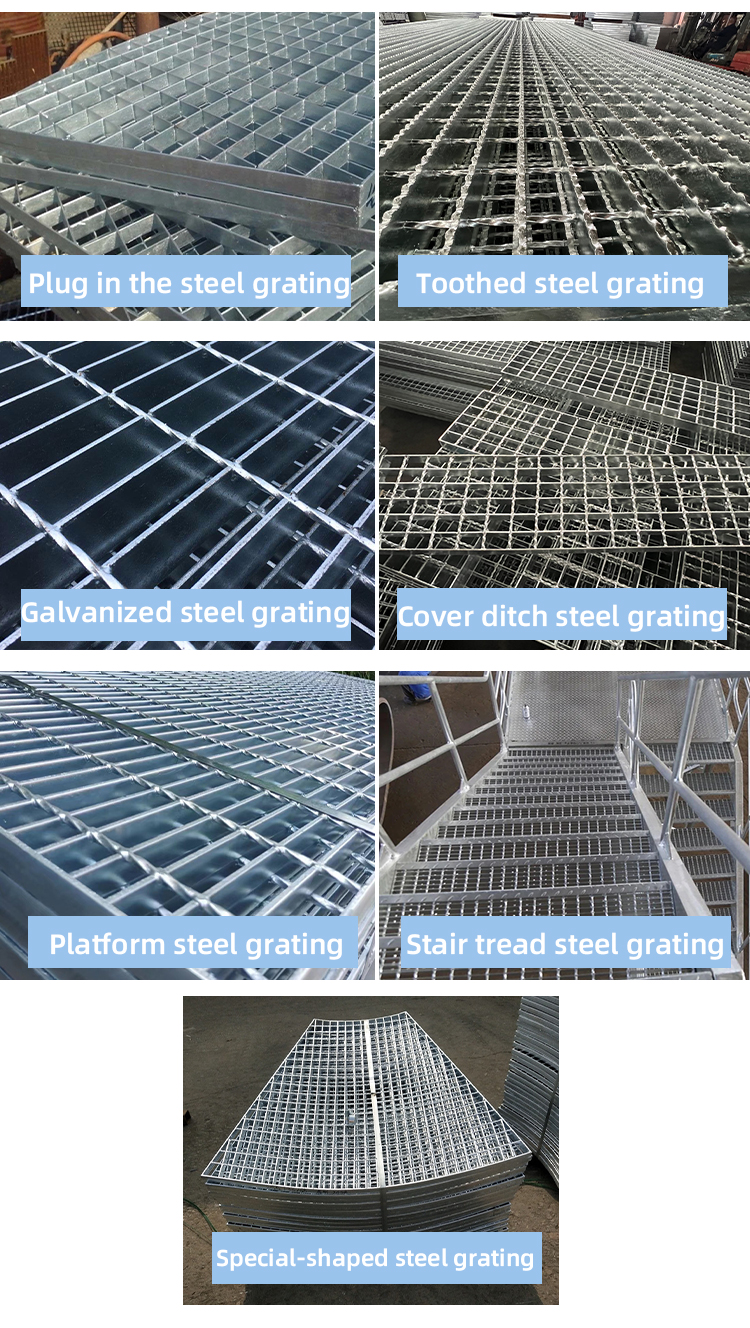

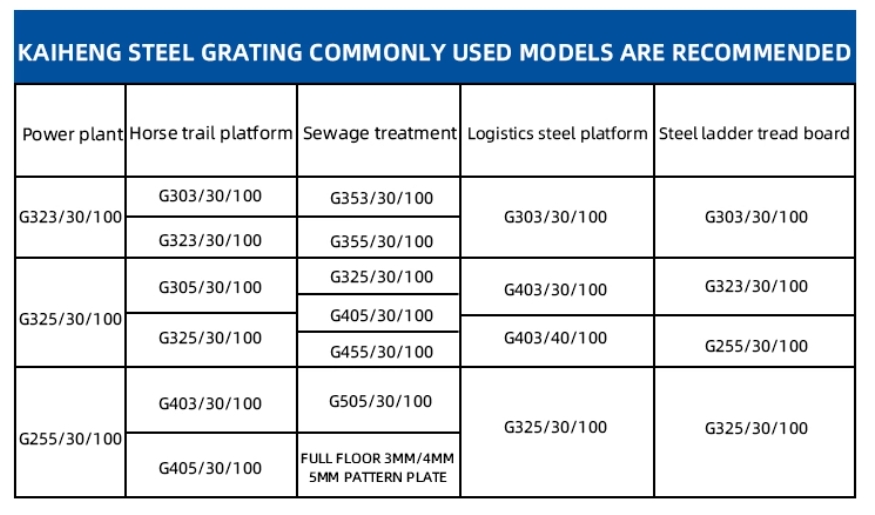

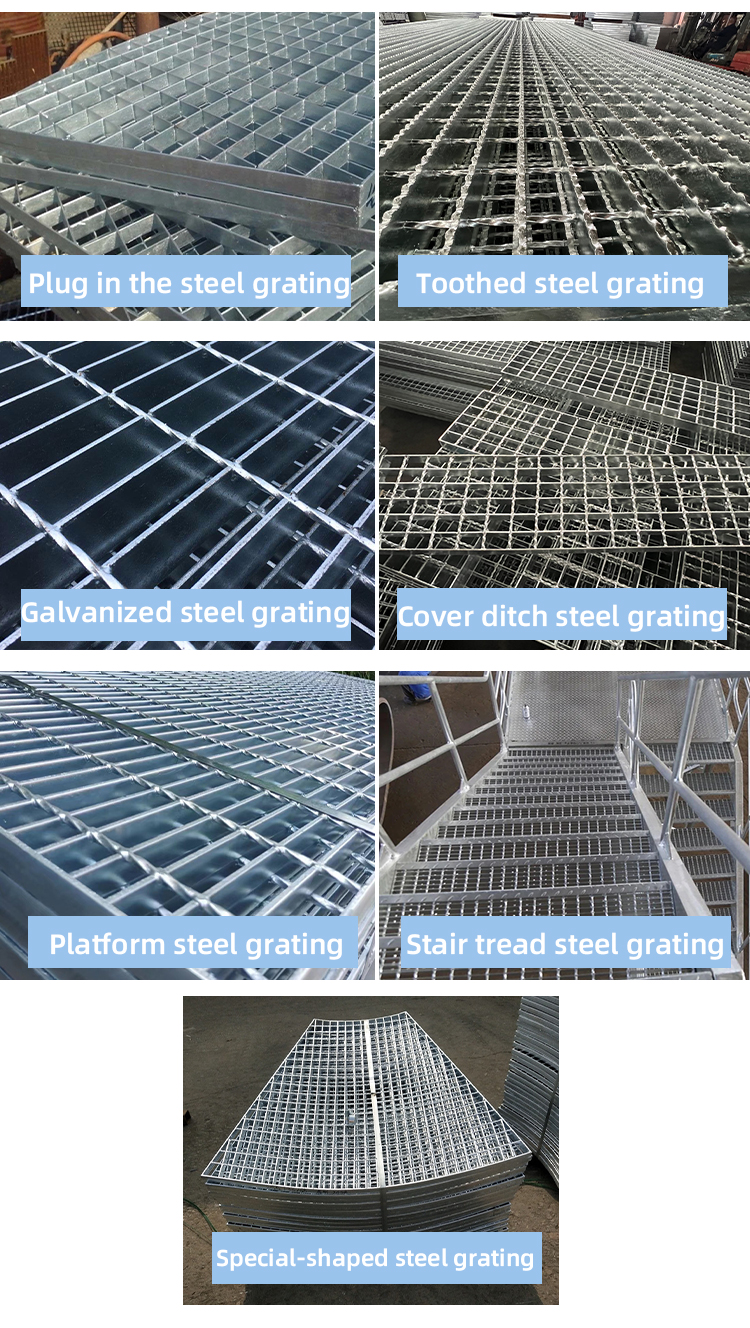

Kinds Of Steel Grating

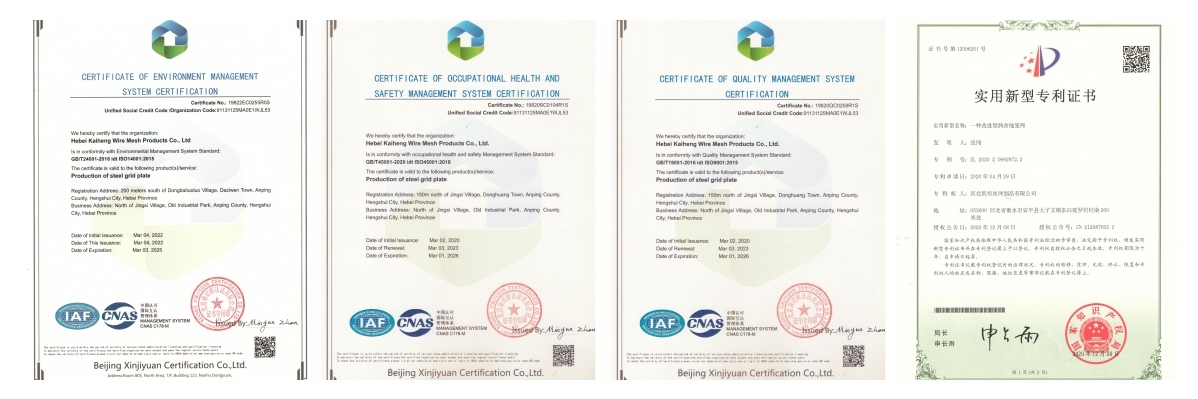

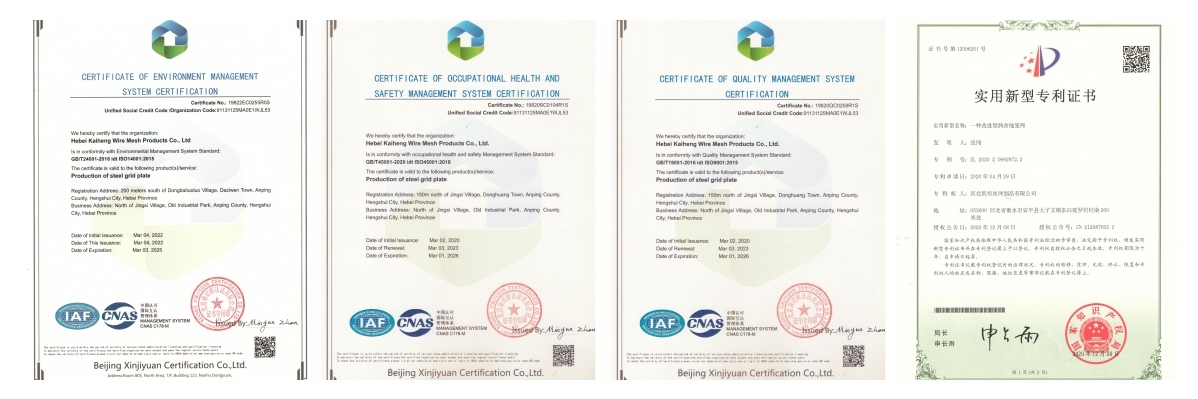

OUR CERTIFICATE

Our Factory Production

Hebei Kaiheng Wire Mesh Products Co. Ltd. is a leading manufacturer of steel grating platesproducing over 3000 plates daily and holding multiple quality certifications, focusing on industriessuch as petrochemical and hydropower.

With a high-end intelligent industrial park integrating production and research and developmentand two patent information items, Kaiheng specializes in the steel grating series and offerscustomized solutions tailored to meet the needs of various customers.