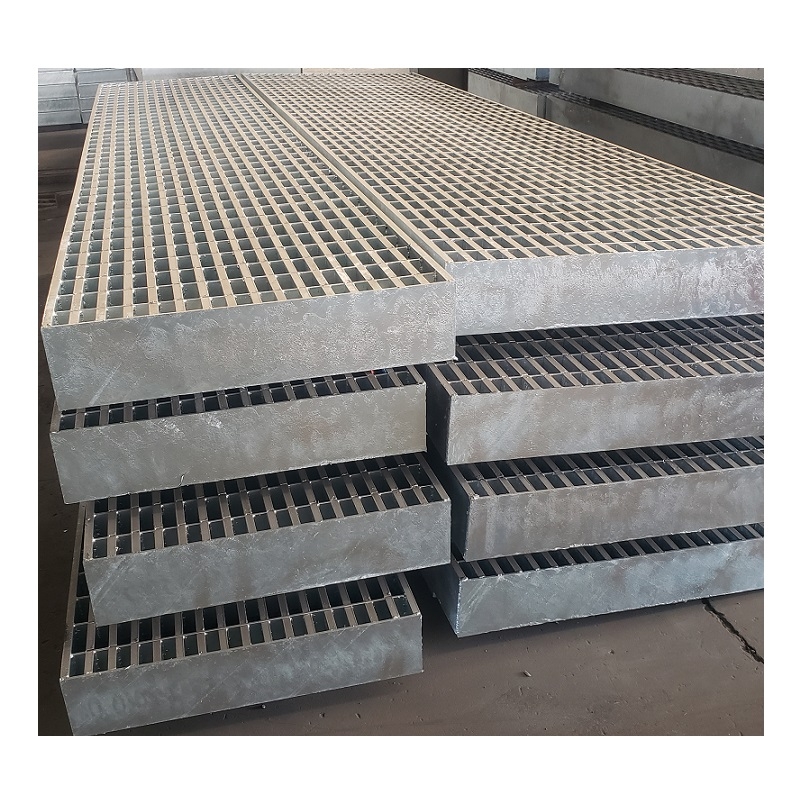

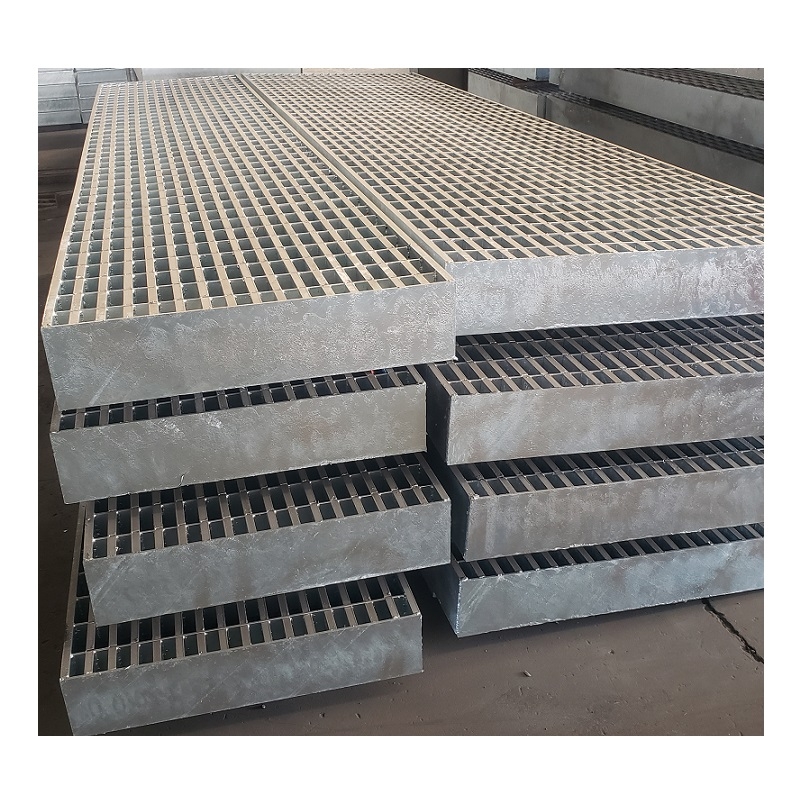

Introduction Of Heavy Duty Steel Grating

Product Overview

Heavy Duty Steel Grating China Gratings represents premium heavy-duty grating manufactured in China’s state-of-the-art facilities equipped with advanced production technology and strict quality control systems. Combining German-engineered production lines that ensure high precision and efficiency with strict ISO 9001 quality control throughout the manufacturing process, from raw material inspection to final product testing, this product delivers industrial-grade performance at competitive price points. Its robust construction, using thick steel bars and strong welding, makes it suitable for extreme-load applications where reliability is mission-critical, such as in heavy industry and infrastructure projects.

Product Specifications

Parameter | Details |

Material | Premium carbon steel (Q460C) with a tensile strength of 460-580MPa, providing exceptional strength |

Length | 5m - 12m (customizable to meet the needs of large-scale industrial projects) |

Width | 1.5m - 3m for covering large areas in industrial facilities |

Thickness of bearing bar | 12mm - 25mm to handle extremely heavy loads |

Galvanized layer thickness | ≥100μm (meeting EN 10346 standards for high-quality galvanizing) |

Load capacity | ≥8000kg/m² (certified by TÜV SÜD, a reputable third-party certification body) |

Features

Industrial-grade Load Capacity

Reinforced bearing bars with a 1:8 span-to-depth ratio, which is optimal for load distribution, support heavy machinery including forklifts (10-ton capacity), container handlers that move large shipping containers, and industrial cranes that lift heavy equipment. The grating maintains structural integrity under dynamic impact loads from material handling operations, such as when heavy objects are dropped or moved quickly, ensuring a safe working environment.

Extreme Environment Resistance

The triple-layer galvanizing process (pre-treatment to clean the steel surface, zinc coating for corrosion protection, sealant to enhance durability) provides 20+ years of corrosion resistance in saltwater environments (ports with exposure to seawater) and chemical exposure (industrial plants with harsh chemicals). It withstands temperature fluctuations from -40°C in cold regions to 120°C in high-temperature industrial settings, ensuring stable performance in extreme conditions.

Cost-effective Durability

While initial investment exceeds standard gratings, the 30-year service life (5x longer than painted steel) results in 67% lower lifecycle costs over the long term. The low-maintenance design eliminates periodic repainting or replacement, reducing labor and material costs associated with maintenance. This makes it a cost-effective choice for industrial applications where downtime and maintenance are expensive.

Application

This grating is industry-standard in port terminals (container yards where containers are stored and moved, ship berths where ships are loaded and unloaded), shipyards (dry docks where ships are repaired, vessel maintenance platforms where workers perform maintenance on ships), mining operations (haul road crossings where heavy mining trucks pass, processing plant floors with heavy equipment and material handling), and heavy industrial facilities (steel mills with high temperatures and heavy machinery, foundries with molten metal handling). It provides stable surfaces for heavy equipment staging areas where machinery is stored and prepared for use, material storage areas where raw materials and finished products are stored, and transportation corridors where goods and equipment are moved, ensuring smooth and safe operations in these demanding environments.

Custom Service

As a China-based manufacturer, we offer OEM/ODM services including custom drilling with precise hole positions and sizes for attaching equipment, cutouts for equipment integration that allow machinery to fit seamlessly with the grating, and specialized packaging for overseas shipping that ensures the grating arrives in good condition. Engineering support includes finite element analysis (FEA) for complex load scenarios to ensure the grating can handle specific loads and conditions, and compliance documentation for global standards (ASTM, BS, DIN) to meet the requirements of international projects. Our team of engineers works closely with customers to provide tailored solutions that meet their specific needs and specifications.