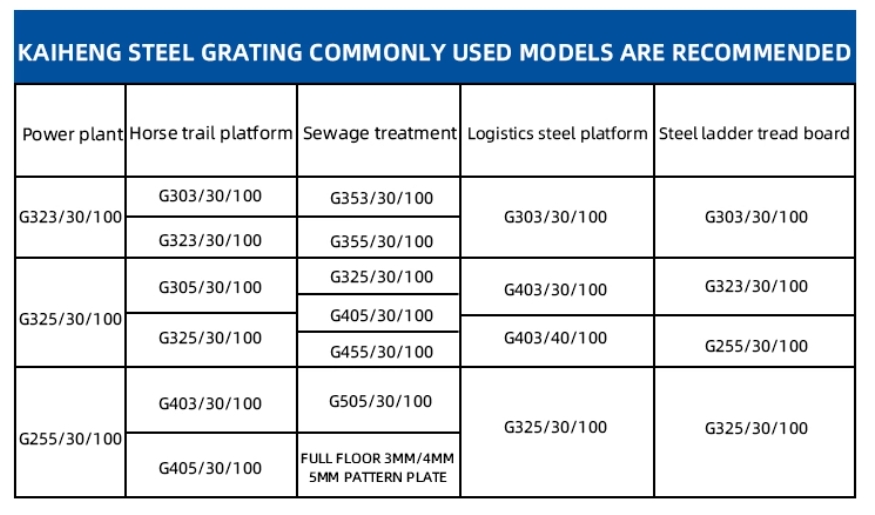

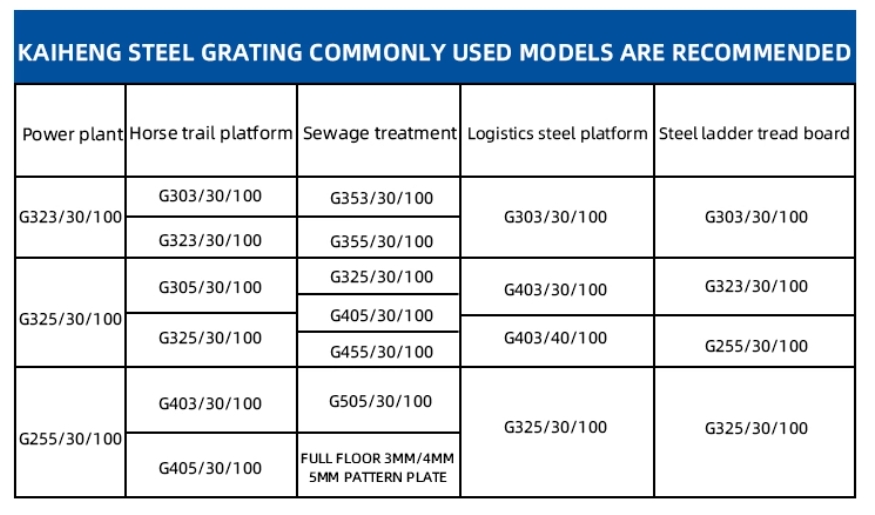

Introduction Of Steel Grating

Heavy Duty Galvanized Steel Grating for Platform Walkways is a high-performance grating product meticulously crafted for platform walkway applications. Manufactured using advanced automated welding technology with precision control systems, each welding point is subjected to rigorous quality checks to ensure firmness and durability. Its heavy-duty nature enables it to withstand substantial pedestrian traffic—including simultaneous movement of 10+ workers—and the frequent transport of light equipment such as tool carts loaded with maintenance gear weighing up to 500kg. This makes it an ideal choice for various industrial and commercial platform walkway settings, from bustling factory floors with constant worker movement to elevated facility catwalks that require reliable support. The hot-dip galvanizing coating undergoes rigorous adhesion testing, including salt spray tests lasting 500 hours, ensuring long-term resistance to corrosion even in high-moisture environments like coastal areas or chemical-exposed environments such as chemical processing plants.

Product Specifications

Parameter | Details |

Material | High-strength carbon steel (Q235B/Q355B) with excellent tensile strength of 375-500MPa |

Length | 2m - 6m (customizable in 0.5m increments to fit specific platform dimensions) |

Width | 0.5m - 1.5m for flexible installation in different walkway widths |

Thickness of bearing bar | 5mm - 12mm to provide varying levels of load support |

Galvanized layer thickness | ≥85μm (conforming to ISO 1461 standards, ensuring superior corrosion resistance) |

Load capacity | ≥500kg/m² (tested under dynamic load conditions simulating real-world pedestrian and equipment movement) |

Features

High Load-bearing Capacity

Engineered with reinforced bearing bars that undergo heat treatment to enhance hardness and strength, combined with optimized crossbar spacing calculated through structural analysis software. It can easily bear concentrated loads from portable machinery (up to 300kg per wheel) while maintaining structural integrity. The uniform weight distribution design, achieved through precise placement of crossbars, prevents localized stress fractures during peak usage, even when multiple workers and equipment are on the walkway simultaneously.

Anti-corrosion Performance

The hot-dip galvanizing process immerses the steel grating in molten zinc at 450°C, a temperature carefully controlled to ensure proper alloy formation. This forms a metallurgically bonded zinc-iron alloy layer that is tightly adherent to the steel surface. This dense coating resists rust and chemical erosion, withstanding exposure to industrial chemicals, saltwater, and moisture, achieving a service life of 15+ years in outdoor industrial environments with minimal maintenance.

Easy Installation & Maintenance

Pre-punched mounting holes with precise positioning accuracy of ±0.5mm and compatible clamp systems that are corrosion-resistant reduce installation time by 40% compared to traditional welding methods. The open grid design with a spacing that allows debris of up to 20mm in diameter to fall through, minimizing cleaning requirements. This design also facilitates drainage, preventing water accumulation and reducing maintenance downtime, making it suitable for busy industrial settings where operational continuity is crucial.

Application

This grating is widely deployed in industrial plants (automotive manufacturing facilities, food processing factories with strict hygiene requirements), power stations (coal-fired power plants with high temperatures, renewable energy facilities such as wind farms), chemical plants (petrochemical refineries, pharmaceutical production plants with corrosive substances), and commercial buildings (shopping mall atriums with high foot traffic, stadium catwalks for event staff). It excels in operation platforms for assembly lines where workers stand for long hours, maintenance platforms around boilers and turbines that require regular inspection, and pedestrian walkways in logistics centers with constant movement of personnel and small carts, providing OSHA-compliant fall protection with a safety factor of 2.5 and slip resistance with a coefficient of friction of ≥0.6.

Custom Service

Our engineering team offers tailored solutions including non-standard lengths up to 8m to accommodate large platform designs, anti-slip serrated surfaces with a tooth depth of 2mm for oily environments common in industrial settings, and color-coated finishes in various RAL colors for aesthetic matching with surrounding structures. CAD drawings with detailed dimensions and load calculation reports based on specific project requirements are provided free for custom projects, ensuring accurate and efficient installation.

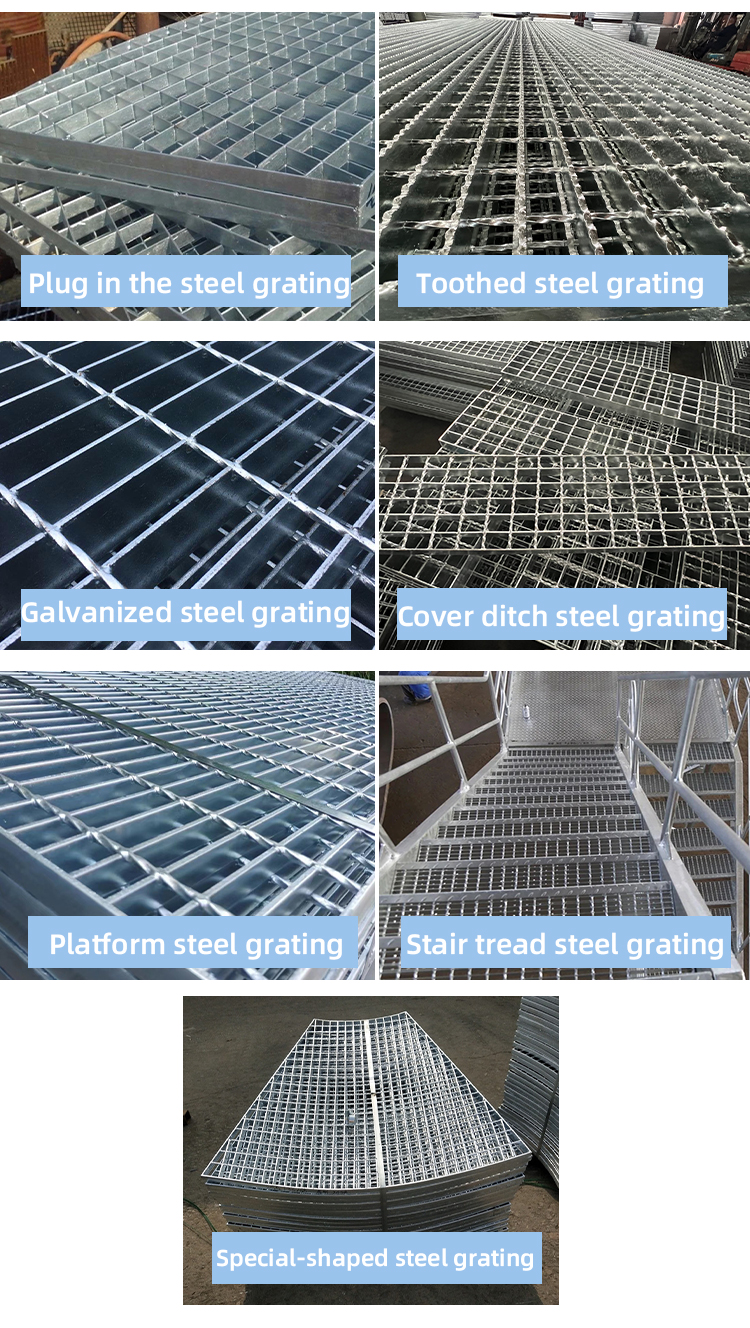

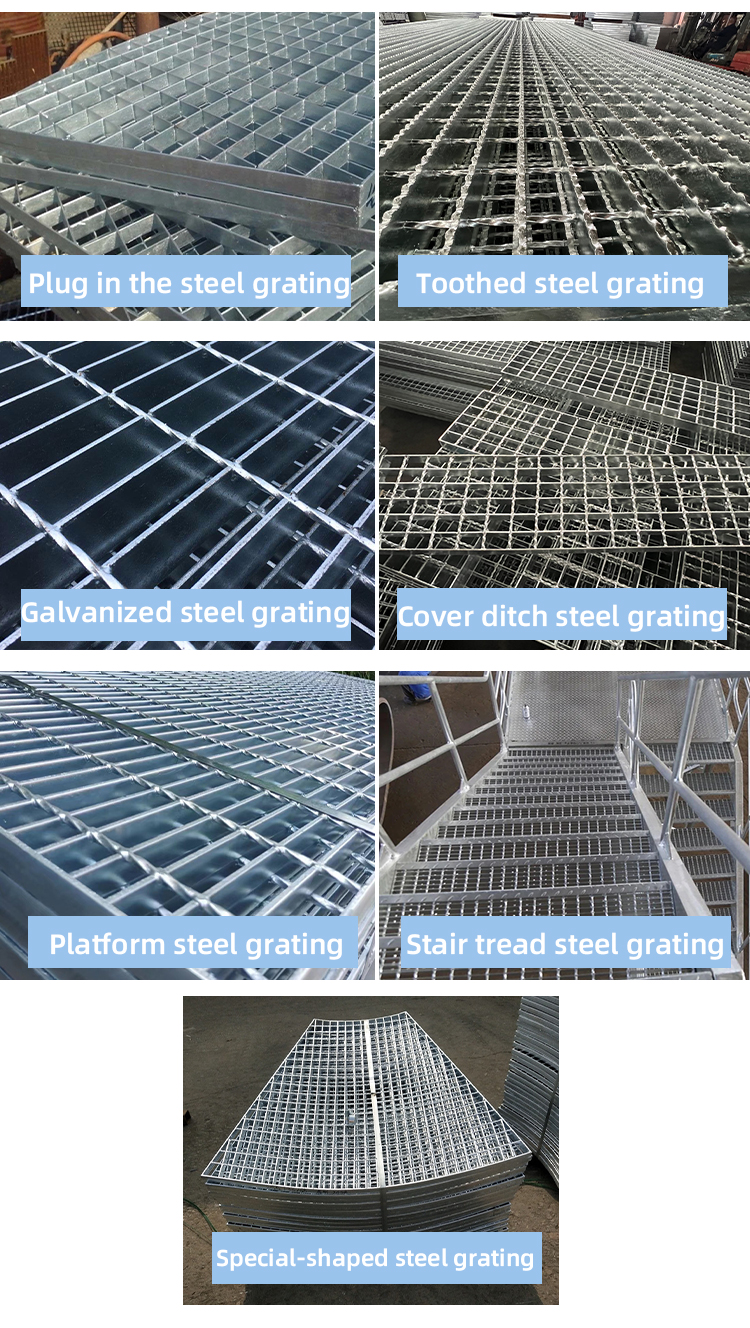

Kinds Of Steel Grating

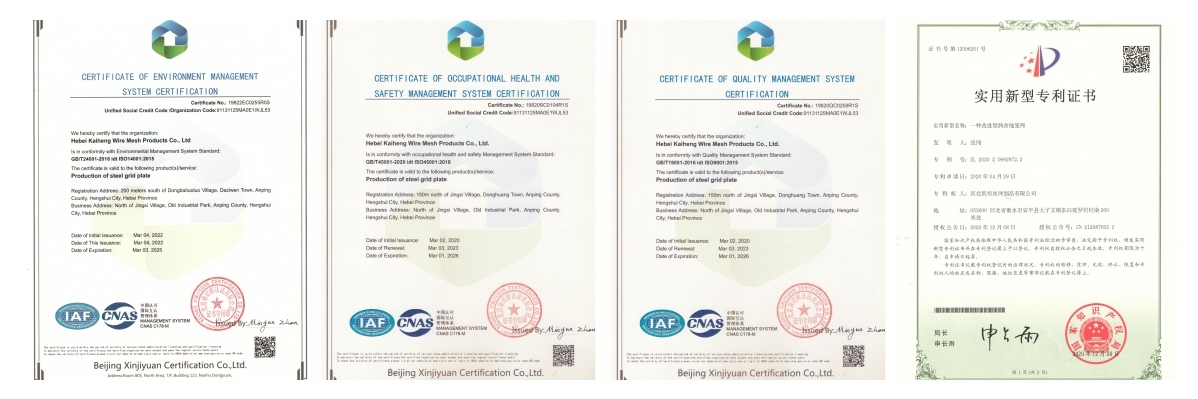

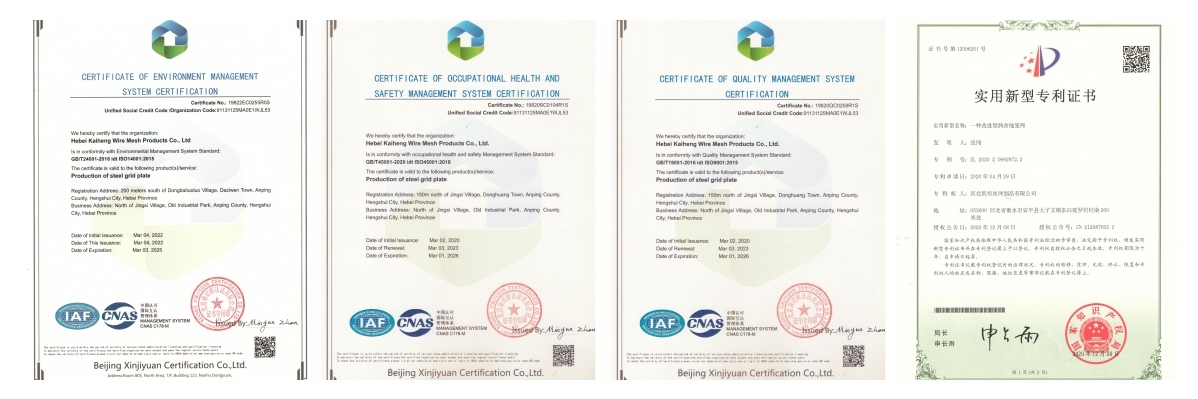

OUR CERTIFICATE

Our Factory Production

Hebei Kaiheng Wire Mesh Products Co. Ltd. is a leading manufacturer of steel grating platesproducing over 3000 plates daily and holding multiple quality certifications, focusing on industriessuch as petrochemical and hydropower.

With a high-end intelligent industrial park integrating production and research and developmentand two patent information items, Kaiheng specializes in the steel grating series and offerscustomized solutions tailored to meet the needs of various customers.