Fiberglass grating has emerged as a vital material across numerous industries, from marine to manufacturing. Known for its durability, corrosion resistance, and lightweight characteristics, it’s a go-to solution for flooring, walkways, platforms, and safety covers in harsh or high-moisture environments. But what exactly is fiberglass grating used for, and why do professionals choose it over traditional materials like steel or aluminum? Let’s dive deep into its wide range of applications and the benefits that make it indispensable.

Understanding Fiberglass Grating: What Makes It Unique?

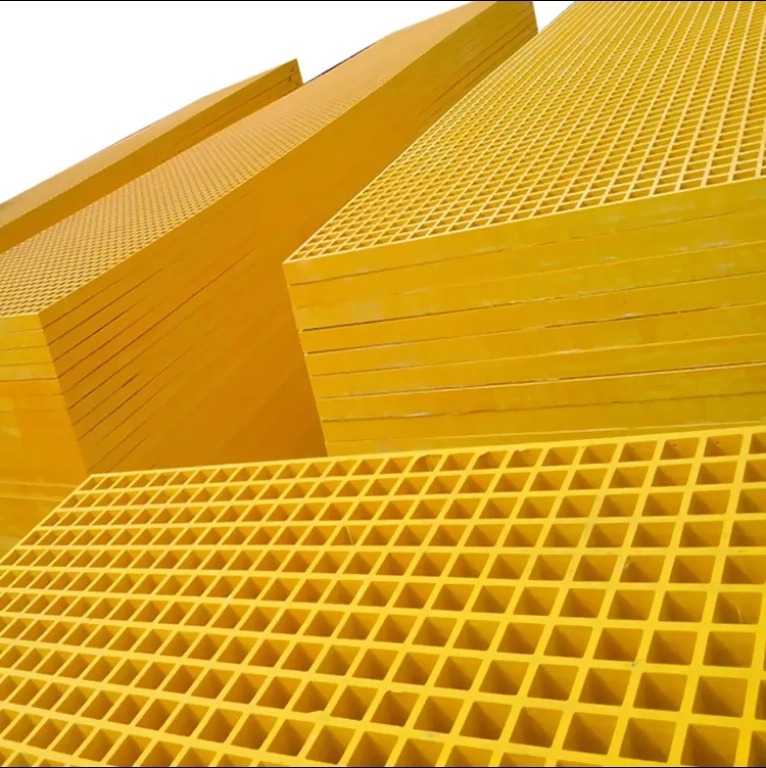

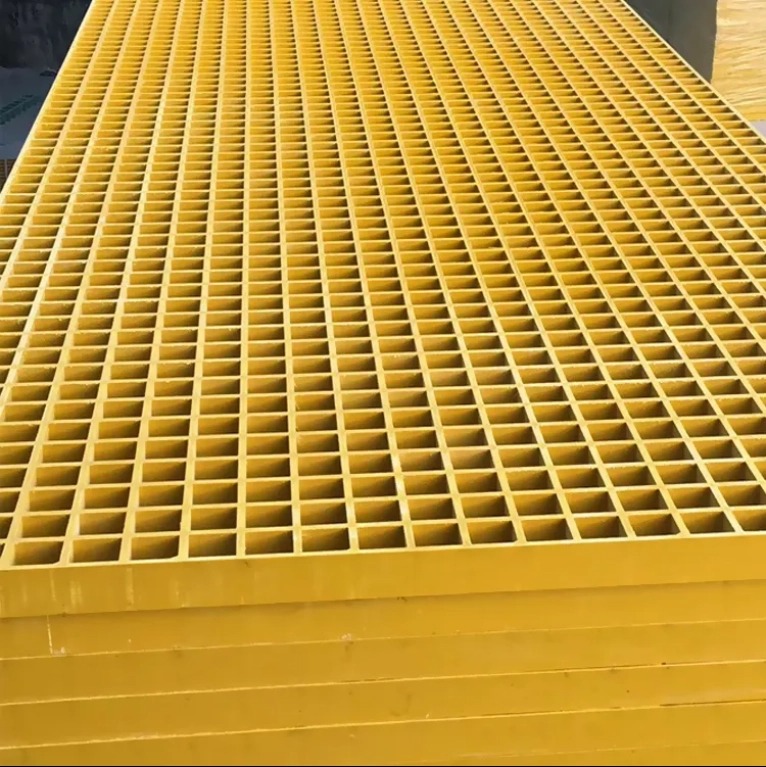

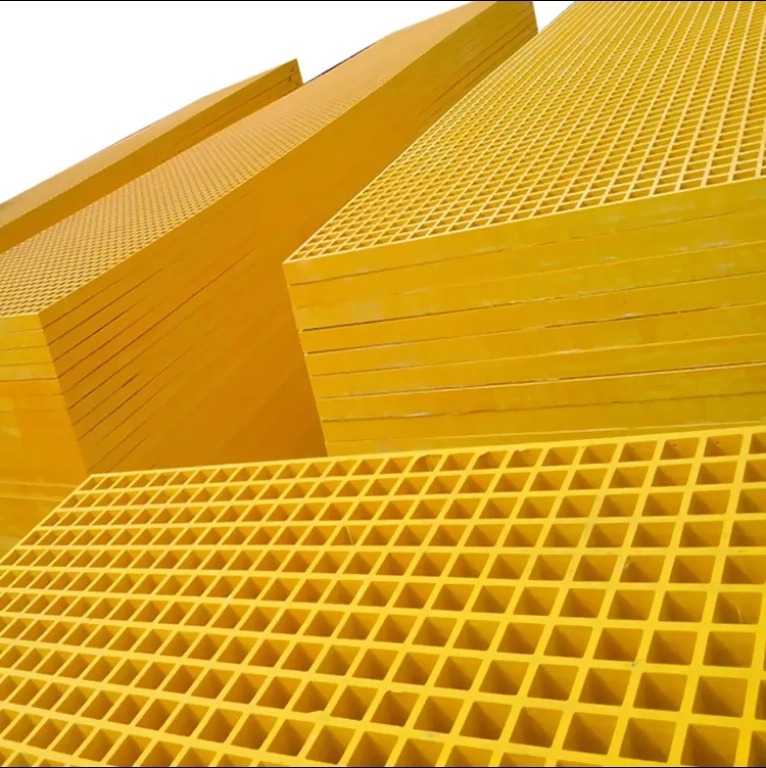

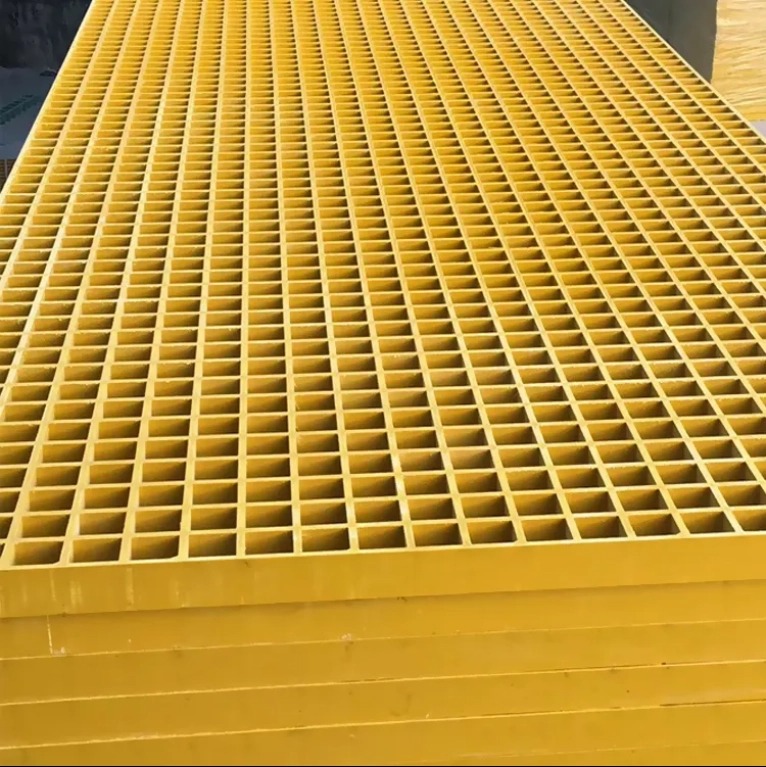

Fiberglass grating, also known as FRP (fiber-reinforced plastic) grating, is made by reinforcing a polymer matrix with glass fibers. This composition gives it superior mechanical strength while maintaining low weight and excellent resistance to corrosion, rust, and chemical exposure. It typically comes in two primary forms: molded and pultruded grating. Molded fiberglass grating is created in a mold and provides multidirectional strength, while pultruded grating is made by pulling fiberglass rovings through a resin, offering high strength in one direction.

One of the most notable qualities of fiberglass grating is its non-conductivity. This makes it ideal for environments where electrical safety is a concern. Moreover, fiberglass grating doesn’t warp, shrink, or expand under extreme temperatures as traditional metals do. It’s also maintenance-free and provides a high strength-to-weight ratio, making installation easier and more cost-effective. These unique characteristics have paved the way for its use in a variety of demanding settings.

Key Industrial Applications of Fiberglass Grating

Fiberglass grating is widely used in industrial sectors that require strong, non-slip, and corrosion-resistant flooring and access systems. These industries include petrochemical plants, food processing facilities, water treatment plants, and power generation sites. In these settings, traditional materials tend to degrade quickly due to exposure to chemicals, humidity, or high temperatures.

In petrochemical plants, fiberglass grating is used for walkways, platforms, and trench covers due to its resistance to harsh chemicals. For food and beverage facilities, it’s a hygienic solution that resists bacterial growth and can be easily cleaned. In wastewater treatment plants, fiberglass grating can withstand continuous exposure to wet and corrosive environments, making it ideal for walkways and platforms over open water channels. Power plants also benefit from fiberglass grating’s electrical insulating properties, reducing the risk of electric shocks during maintenance activities.

Marine and Coastal Environments: Built to Withstand Salt and Moisture

Marine environments are some of the most challenging areas for structural materials due to the constant presence of saltwater, UV exposure, and high humidity. Fiberglass grating excels in these conditions. It’s widely used on docks, boat ramps, marinas, offshore platforms, and ship decks. Its corrosion resistance ensures it won’t rust or weaken over time, which is critical in maintaining structural integrity and safety in coastal infrastructure.

Additionally, fiberglass grating’s non-slip surface makes it perfect for wet areas where the risk of slipping is high. In ports and harbors, where equipment and personnel move constantly, having a safe, stable, and low-maintenance surface is crucial. Traditional steel surfaces corrode quickly in these environments, requiring regular replacement or maintenance. In contrast, fiberglass grating lasts longer and requires minimal upkeep, making it a cost-effective and safe choice for maritime applications.

Architectural and Urban Use: Style Meets Function

In recent years, fiberglass grating has found its way into architectural and urban design. It’s now common to see FRP grating used in pedestrian walkways, rooftop access, public spaces, stair treads, and even decorative facades. Its sleek, grid-like appearance can be tailored to suit a range of aesthetic preferences without sacrificing functionality.

Urban planners and architects appreciate fiberglass grating for its lightweight and modular nature, making it easy to install in tight or elevated spaces. Additionally, its ability to be manufactured in various colors and textures allows for creative applications that still meet stringent safety requirements. For instance, fiberglass grating can be used in urban water features or storm drain covers where both visual appeal and functional strength are important.

Safety First: Fiberglass Grating in Hazardous Work Environments

One of the major uses of fiberglass grating is in environments where safety is the top priority. This includes oil rigs, mining operations, manufacturing plants, and chemical processing facilities. These are locations where exposure to electrical equipment, chemicals, slippery surfaces, and fire hazards is frequent. Fiberglass grating offers slip-resistant surfaces, flame-retardant properties, and electrical insulation—all critical safety factors.

Its non-conductive nature reduces the risk of electrical accidents, while its fire-retardant resins prevent the rapid spread of flames. Moreover, its high visibility (thanks to customizable colors like safety yellow or orange) ensures that hazard zones are easily marked. Because fiberglass grating is often manufactured to meet OSHA and ASTM standards, it’s frequently chosen for safety compliance in workspaces where employee protection is paramount.

Frequently Asked Questions (FAQs) about Fiberglass Grating

| Question | Answer |

| Is fiberglass grating stronger than steel? | It has a high strength-to-weight ratio but isn’t stronger than steel in absolute terms. However, it performs better in corrosive environments. |

| Can fiberglass grating be used outdoors? | Absolutely. It’s UV resistant and ideal for outdoor applications like decks, platforms, and pedestrian walkways. |

| Is it difficult to install? | No. Its lightweight nature makes it easier and faster to install compared to metal alternatives. |

| What sizes does it come in? | Fiberglass grating is available in a range of panel sizes, thicknesses, and mesh configurations to meet various application needs. |

| How do you maintain fiberglass grating? | It requires minimal maintenance. Occasional cleaning with water and mild detergent is sufficient for most environments. |

Conclusion

Fiberglass grating is not just a replacement for traditional materials—it’s a superior alternative in many cases. Its resistance to corrosion, ease of installation, and versatility across diverse industries make it a smart investment for businesses and municipalities alike. Whether you’re operating in a chemical plant or designing an urban space, fiberglass grating provides the strength, safety, and performance needed to excel in harsh or demanding environments.