Introduction

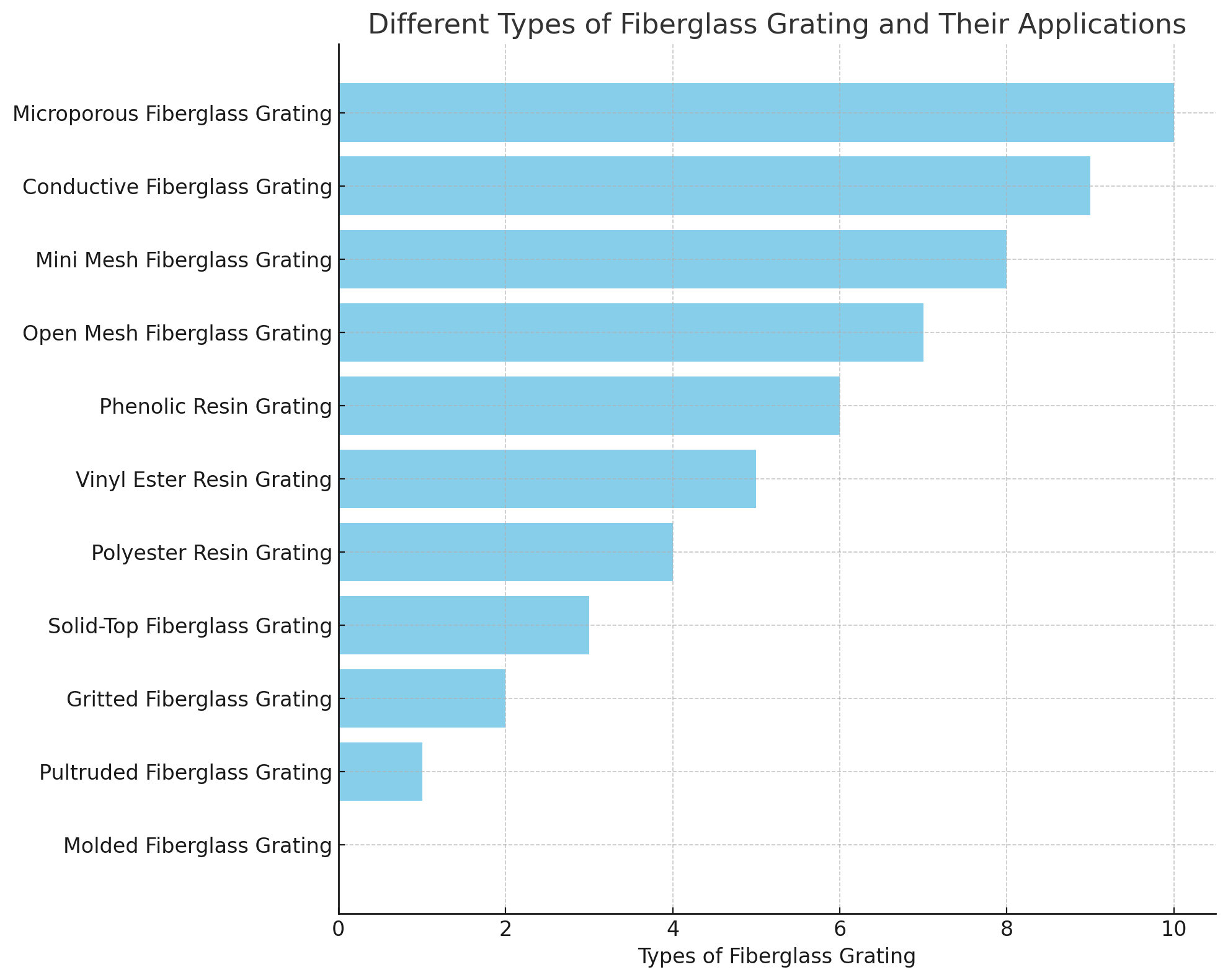

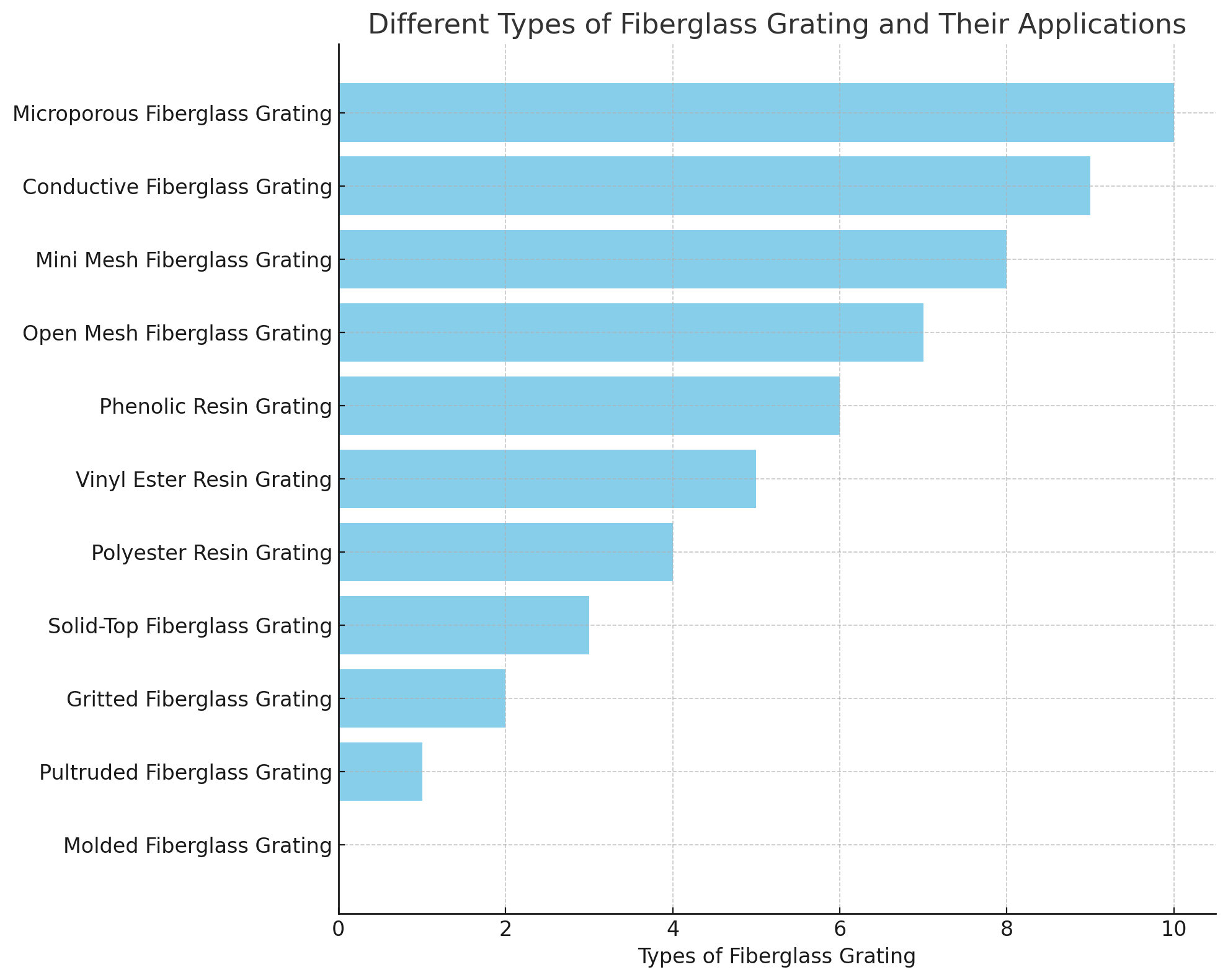

Fiberglass grating is quickly becoming the material of choice across various industries for its strength, corrosion resistance, and lightweight nature. It's an ideal alternative to metal grating in numerous applications, from industrial flooring to pedestrian walkways. Understanding the different types of fiberglass grating is crucial to selecting the right option for each specific need. In this article, we will explore the various types of fiberglass grating, their features, applications, and the best use cases for each.

Types of Fiberglass Grating Based on Manufacturing Process

Molded Fiberglass Grating

Characteristics:

Molded fiberglass grating is made by placing fiberglass rovings and resin into a mold, which is then heated and cured. This type of grating has bi-directional strength, meaning it performs well under load from any direction. It is highly impact-resistant and flexible, which makes it suitable for a variety of environments.

Applications:

Ideal for use in industrial walkways, platforms, and areas requiring high load-bearing capacity. Molded grating is also common in chemical plants, wastewater facilities, and areas exposed to harsh chemicals due to its corrosion resistance.2.2. Pultruded Fiberglass Grating

Strength and Durability:

Pultruded fiberglass grating is manufactured by pulling fiberglass strands through a resin bath and then shaping them under heat and pressure. This process results in a product that is stronger in one direction, making it suitable for applications requiring high tensile strength and load-bearing capability.

Uses:

Pultruded grating is commonly used in heavy-duty applications such as bridges, ramps, and high-load platforms. Its high strength and corrosion resistance make it a great choice for demanding environments like offshore platforms or industrial plants.

Types of Fiberglass Grating Based on Surface Type

Gritted Fiberglass Grating

Non-slip Surface:

Gritted fiberglass grating has a rough, textured surface that significantly reduces the risk of slipping. This surface treatment is ideal for wet and slippery environments.

Common Uses:

It is often used in industrial areas, walkways, stairs, and locations where safety is a concern, such as in factories, warehouses, and marine environments.

Solid-Top Fiberglass Grating

Full Surface Coverage:

Solid-top fiberglass grating is designed to block debris and liquids from passing through the grating. This type of grating provides a smooth, continuous surface ideal for applications where safety and hygiene are a priority.

Applications:

Solid-top fiberglass grating is perfect for food processing plants, pharmaceutical facilities, and warehouses. It is commonly used in environments where dirt, debris, or liquids need to be contained or redirected.

Types of Fiberglass Grating Based on Resin Type

Polyester Resin Fiberglass Grating

Corrosion Resistance:

Polyester resin-based fiberglass grating offers good corrosion resistance at a cost-effective price. It is ideal for general industrial use in less aggressive environments.

Applications:

This type of grating is suitable for use in industrial platforms, walkways, and other settings where exposure to moisture or mild chemicals is expected.

Vinyl Ester Resin Fiberglass Grating

Chemical Resistance:

Vinyl ester resin is known for its superior resistance to harsh chemicals, including acids and alkalis. It provides excellent protection in environments with frequent exposure to aggressive substances.

Applications:

Ideal for chemical plants, refineries, laboratories, and other facilities where chemical exposure is a constant concern.

Phenolic Resin Fiberglass Grating

Flame Resistance:

Phenolic resin-based grating offers excellent flame retardancy and low smoke production. It is specifically designed to resist fire and heat, making it the best choice for environments that require fire safety.

Applications:

Phenolic fiberglass grating is commonly used in offshore platforms, fire-sensitive industrial areas, and environments with high-temperature operations.

Types of Fiberglass Grating Based on Mesh Size

Open Mesh Fiberglass Grating

Maximum Drainage and Ventilation:

Open mesh fiberglass grating features large spaces between the bars, allowing for maximum drainage and ventilation. This type of grating is ideal for environments where water accumulation and airflow are critical.

Ideal Uses:

Wet environments, wastewater treatment plants, and marine platforms are common areas where open mesh grating is used. It is also popular in outdoor applications like bridges and docks.

Mini Mesh Fiberglass Grating

Small Apertures:

Mini mesh grating has smaller gaps between the bars, preventing small items from falling through. It offers a more compact design while still providing the benefits of fiberglass grating.

Applications:

Perfect for pedestrian areas, transport hubs, and public spaces where small objects might pose a risk. It is also a great choice for areas with wheelchair accessibility requirements.

Specialty Fiberglass Grating Types

Conductive Fiberglass Grating

Electrical Conductivity:

Conductive fiberglass grating is designed to prevent the buildup of static electricity by incorporating a conductive layer on its surface. This feature is especially important in industries where static discharge could cause problems.

Applications:

Commonly used in electronics manufacturing, refineries, and high-tech industries where electrostatic discharge is a concern.

Microporous Fiberglass Grating

Fine Mesh Design:

Microporous fiberglass grating features smaller apertures that prevent smaller objects from passing through. Its fine mesh design makes it ideal for areas where small items need to be contained.

Ideal for:

Applications requiring small debris prevention, such as in semiconductor plants, computer rooms, and areas with wheelchair access.

Applications of Different Types of Fiberglass Grating

Industrial Applications

For industrial environments that demand durability and resistance to chemicals or heavy loads, choosing the right type of fiberglass grating is essential. Molded and pultruded gratings are ideal for industrial flooring, catwalks, and platforms due to their high strength and chemical resistance.

Commercial and Public Infrastructure

Fiberglass grating is increasingly being used in public infrastructure due to its safety and aesthetic qualities. Anti-slip grating, such as gritted and mini-mesh types, are ideal for pedestrian walkways, transport hubs, and outdoor areas like parks or stadiums.

Marine and Offshore Applications

Fiberglass grating's corrosion resistance is a major asset in marine and offshore environments. Open mesh fiberglass grating is particularly useful in these settings due to its drainage and ventilation properties, making it ideal for docks, offshore platforms, and water treatment facilities.

Conclusion

Fiberglass grating comes in various types, each designed for specific applications, such as manufacturing processes, surface types, resin compositions, and mesh sizes. Choosing the right type ensures optimal performance, safety, and longevity. Whether you need high strength, chemical resistance, or fire safety, understanding these types will help you make the best choice for your needs. Businesses can benefit from the durable and versatile fiberglass grating solutions offered by Kaiheng, tailored to industry-specific requirements. For the best results, always consult with the manufacturer to ensure the right selection based on environmental conditions and application needs. Kaiheng provides customizable, high-performance fiberglass grating solutions.

FAQ

Q: What are the different types of fiberglass grating?

A: There are several types of fiberglass grating, including molded, pultruded, gritted, solid-top, and microporous grating. Each type is designed for specific applications, such as industrial use, pedestrian areas, or environments requiring chemical or fire resistance.

Q: What is molded fiberglass grating used for?

A: Molded fiberglass grating offers bi-directional strength and impact resistance. It's ideal for walkways, platforms, and industrial settings where durability is crucial.

Q: How does pultruded fiberglass grating differ from molded grating?

A: Pultruded fiberglass grating has higher strength in one direction, making it suitable for heavy-load applications like bridges and ramps. Molded grating is more flexible and resistant to impact.

Q: What applications benefit from solid-top fiberglass grating?

A: Solid-top fiberglass grating provides full surface coverage, making it ideal for industries like food processing and manufacturing, where preventing debris and liquids from passing through is important.

Q: Why is it important to choose the right resin type for fiberglass grating?

A: Choosing the correct resin ensures the grating's performance in specific environments. Polyester, vinyl ester, and phenolic resins offer varying levels of corrosion, chemical, and fire resistance.