Introduction

Fiberglass grating walkways are becoming essential in industries like manufacturing and wastewater treatment. Their strength, light weight, and corrosion resistance make them ideal for many applications. But how much weight can they really support?

In this article, we’ll explore the factors that influence the weight-bearing capacity of fiberglass grating walkways. You’ll learn how to assess load ratings and apply the right grating type for different situations.

Understanding Load Ratings for Fiberglass Grating Walkways

Types of Load Ratings

Uniform Loads (UL)

Uniform loads are distributed evenly across the surface of the fiberglass grating walkway. This type of load is measured in pounds per square foot (psf) or kilonewtons per meter squared (kN/m²). It reflects situations where the weight is evenly spread out, such as pedestrian traffic or maintenance equipment moving across a walkway.

Concentrated Loads (CL)

Concentrated loads, on the other hand, apply pressure to a smaller, more localized area. Examples include heavy equipment or caster wheels that focus weight on a specific point. These loads are measured in pounds or kilonewtons and are typically tested at mid-span to ensure the grating can handle localized stress.

Design Standards and Regulations

Several standards ensure fiberglass grating walkways are safe and meet the required load capacity:

ANSI/NAAMM FG-1

This is the standard used in North America to determine the deflection limits for molded and pultruded fiberglass grating. It ensures that fiberglass grating can bear a specified load without excessive deflection, which could compromise safety.OSHA 1910.29

OSHA regulations require elevated platforms to support a minimum live load of 50 psf. In addition, concentrated loads must be checked to ensure the walkway will not fail under point pressure from equipment or personnel.EN 13706

In Europe, the EN 13706 standard is used to test and classify the strength and modulus of pultruded fiberglass grating. It’s essential for determining load-bearing capacity in various industrial environments.

Factors Influencing the Weight Capacity of Fiberglass Grating Walkways

Material Composition and Resin Types

The resin used in the production of fiberglass grating plays a significant role in its load capacity. The two most common resins are:

● Polyester Resin: Offers standard corrosion resistance and is suitable for general industrial applications.

● Vinyl Ester Resin: Provides superior chemical resistance, making it ideal for harsh chemical environments.

● Phenolic Resin: Known for its high flame resistance, making it suitable for fire-sensitive areas.

Additionally, the glass content in the grating determines its tensile strength. Higher glass content results in higher strength and load-bearing capacity, ensuring the grating performs well under heavier loads.

Grating Geometry and Bar Types

The type of grating—whether molded or pultruded—affects its ability to bear weight:

● Molded Grating: Offers bi-directional strength, making it effective for a variety of applications. Its load capacity depends on thickness and material choice.

● Pultruded Grating: Designed for heavier loads, pultruded grating typically has higher strength in one direction, making it suitable for long spans and heavy-duty applications.

The geometry of the bars also impacts the overall load-bearing capacity. I-bars and T-bars are common configurations, with I-bars providing higher load-bearing capacity due to their design.

Support and Span Configuration

The span length between supports has a direct influence on the weight capacity of fiberglass grating walkways. Longer spans result in lower load-bearing capacity, while shorter spans provide greater strength and stability. Additionally, the spacing of the clips that hold the grating in place affects its ability to support weight. Proper clip placement ensures even distribution of load and minimizes deflection.

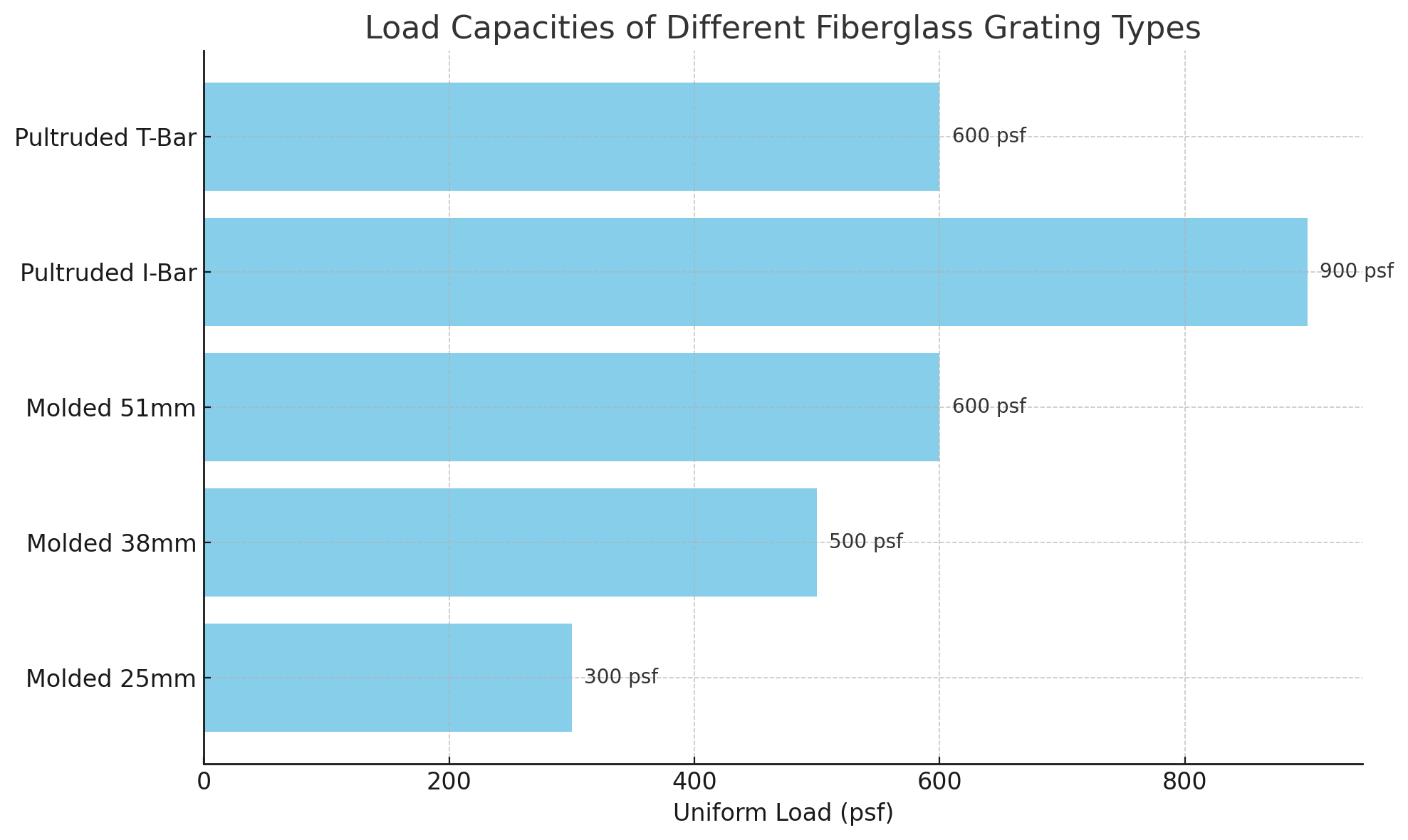

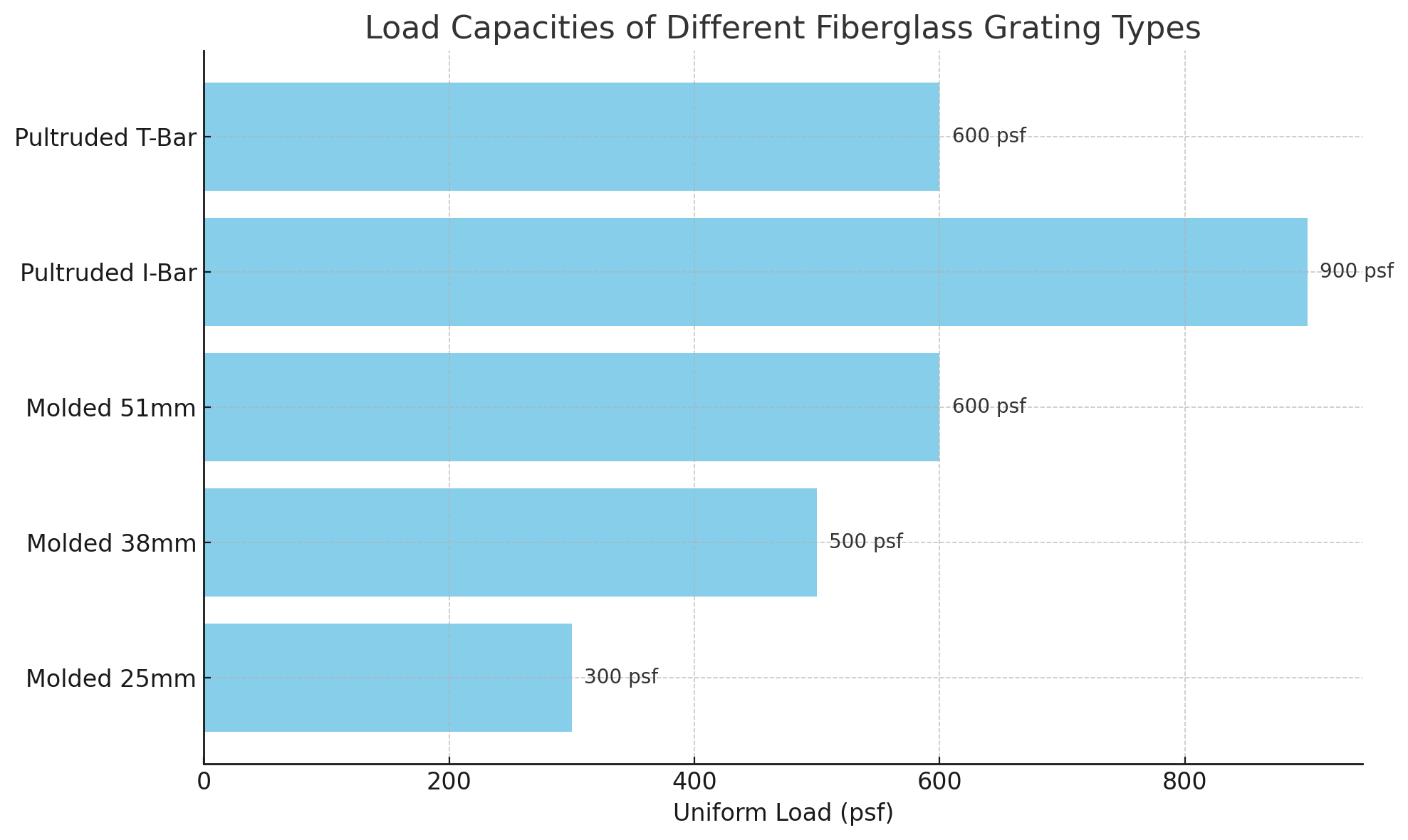

Typical Load Capacities Based on Grating Type and Thickness

Molded Grating Load Ranges

25 mm Thickness

● Maximum span: 610 mm

● Uniform load: 300 psf (14 kN/m²)

● Common use: Catwalks, HVAC service pads

38 mm Thickness

● Maximum span: 915 mm

● Uniform load: 500 psf (24 kN/m²)

● Common use: Clarifier bridges

51 mm Thickness

● Maximum span: 1220 mm

● Uniform load: 600 psf (29 kN/m²)

● Common use: Heavy-duty trench covers

Pultruded Grating Load Ranges

I-Bar Grating

● 610 mm span → 900 psf uniform load

● 915 mm span → 600 psf uniform load

● 1220 mm span → 300 psf uniform load

Pultruded I-bars have a higher load-bearing capacity compared to molded grating and are typically used in applications where heavy equipment or foot traffic is expected.

Grating Type | Thickness (mm) | Max Span (mm) | Uniform Load (psf) | Common Applications |

Molded Grating | 25 | 610 | 300 | Catwalks, HVAC service pads |

Molded Grating | 38 | 915 | 500 | Clarifier bridges |

Molded Grating | 51 | 1220 | 600 | Heavy-duty trench covers |

Pultruded I-Bar | 51 | 610 | 900 | Industrial walkways, platforms |

Pultruded I-Bar | 51 | 915 | 600 | Industrial walkways, platforms |

Pultruded I-Bar | 51 | 1220 | 300 | Heavy-duty industrial areas |

Real-World Applications and Case Studies

Case Study: Wastewater Treatment Plant Walkway

A wastewater treatment plant required a walkway to support a 3-ton lime slurry cart. By utilizing 51 mm thick pultruded I-bar grating with a 750 mm span, tests showed that the walkway could bear the load with only a 4 mm deflection, well within the FG-1 standard. This case demonstrated the reliability of fiberglass grating in handling heavy loads while maintaining performance over time.

Case Study: Industrial Walkway in Chemical Plant

In a chemical plant, fiberglass grating was used for walkways and platforms exposed to harsh chemicals and UV rays. The molded and pultruded grating was selected based on the required thickness and load-bearing capacity, providing both chemical resistance and structural integrity.

Comparing Fiberglass Grating to Other Grating Materials

Strength-to-Weight Ratio

Fiberglass grating offers a 3–4 times higher strength-to-weight ratio compared to galvanized steel, making it ideal for applications where reducing weight is crucial. This also results in lower installation costs and easier handling.

Corrosion Resistance and Maintenance

Unlike steel grating, which may require frequent maintenance and repainting, fiberglass grating requires minimal upkeep due to its corrosion-resistant properties. This leads to long-term cost savings, especially in industrial settings exposed to harsh chemicals or salty environments.

Engineering Tips for Optimizing Load Capacity

Selecting the Right Grating Based on Load Map

To optimize load capacity, choose the appropriate grating thickness based on the load map and deflection limits. Reducing span lengths or adding support stringers can help distribute the load more evenly, minimizing deflection and improving overall performance.

Correct Fastening and Clip Placement

Proper clip spacing and edge banding are essential for maintaining the strength of fiberglass grating. Ensuring clips are placed at the correct intervals helps control deflection and prevents potential failure under heavy loads.

Regular Inspection and Non-Destructive Testing

Regular inspections are critical to ensure that fiberglass grating walkways continue to perform at their optimal capacity. Non-destructive testing methods, such as hammer tap and ultrasonic testing, can help detect issues before they impact load-bearing performance.

Conclusion

Understanding how much weight fiberglass grating walkways can hold is crucial for safe and durable designs in industrial settings. Factors like material type, span length, and environmental stressors influence the weight capacity. Proper installation and regular maintenance ensure long-lasting performance.

For reliable, customized solutions, businesses should consult Kaiheng, which offers corrosion-resistant grating tailored to meet specific needs, ensuring both safety and cost-effectiveness.

FAQ

Q: How much weight can a fiberglass grating walkway hold?

A: The weight capacity of a fiberglass grating walkway depends on factors such as grating type, thickness, span, and support. Typical molded grating can hold up to 600 psf, while pultruded grating can handle more, up to 900 psf, depending on the span and design.

Q: What factors affect the weight capacity of fiberglass grating walkways?

A: Key factors include material composition (resin types), grating geometry (I-bar vs. T-bar), span length, and clip spacing. Environmental conditions like temperature and chemicals can also impact load-bearing performance.

Q: Is fiberglass grating suitable for heavy-load applications?

A: Yes, pultruded fiberglass grating is ideal for heavy-load applications, offering high strength in one direction. It can handle significant concentrated loads and is commonly used in industrial platforms and walkways.

Q: How do I calculate the load capacity of fiberglass grating?

A: To calculate the load capacity, determine the span between supports, the grating thickness, and the expected load type (uniform or concentrated). Manufacturers often provide load rating tables for accurate calculations.

Q: Can fiberglass grating handle forklift traffic?

A: Standard molded fiberglass grating is not suitable for forklift traffic. For such applications, pultruded fiberglass grating with a solid top or thicker panels is recommended.

Q: How often should fiberglass grating walkways be inspected for load-bearing capacity?

A: Fiberglass grating walkways should be inspected regularly, especially in high-traffic areas. Annual visual inspections and periodic non-destructive testing (NDT) help detect issues like deflection or wear.