Introduction

Fiberglass grating is gaining traction in various industries due to its unique properties. It outperforms traditional materials like steel and wood, especially in demanding environments. But what makes fiberglass grating so popular?

In this article, we’ll explore its composition, manufacturing methods, and key benefits. You’ll learn why fiberglass grating is becoming a go-to solution in construction and industrial applications.

What is Fiberglass Grating?

Definition and Composition

Fiberglass grating is a type of composite material made by combining glass fibers with resin. This combination, known as fiberglass reinforced plastic (FRP), creates a material that is strong, lightweight, and resistant to environmental stressors. The glass fibers provide tensile strength, while the resin binds the fibers together and adds corrosion resistance.

Fiberglass grating is widely used in settings where metal or wooden grating would degrade quickly due to corrosion, exposure to chemicals, or heavy foot traffic. Its main components—fiberglass and resin—make it ideal for demanding environments like chemical processing, water treatment, and offshore applications.

Manufacturing Methods

Fiberglass grating is produced in two main methods: molded and pultruded.

● Molded Grating: In this process, continuous strands of fiberglass are combined with resin inside a mold to create a solid grating panel. This method is ideal for applications requiring multi-directional strength and can withstand impacts and harsh chemicals. Molded fiberglass grating is particularly popular in industrial flooring, walkways, and platforms.

● Pultruded Grating: Pultrusion is a continuous process where fiberglass rovings are pulled through a resin bath and then shaped into long, flat bars. These bars are then assembled into a grating system. Pultruded grating offers higher strength and load-bearing capacity than molded grating, making it ideal for applications where heavy-duty support is required.

How is Fiberglass Grating Made?

Molding Process

The molding process begins by layering resin and fiberglass in a carefully designed mold. The resin saturates the fiberglass strands and bonds them together, creating a durable and corrosion-resistant panel. This process is repeated in layers to ensure uniform thickness and strength.

After the grating is molded, it is cured using heat to solidify the material. The finished product is then removed from the mold, cut to size, and prepared for use. This method allows for a variety of mesh patterns and sizes, making it customizable for different applications.

Pultrusion Process

In pultrusion, fiberglass strands are pulled through a resin bath, then through a heated die where they are shaped and cured into solid bars. This process results in a stronger, more resilient grating system compared to molded grating. Pultruded fiberglass is ideal for applications that require higher strength-to-weight ratios, like heavy-duty platforms or walkways in industrial plants.

The pultrusion process also allows for greater control over the material’s properties. By adjusting the resin and fiberglass ratio, manufacturers can create grating that meets specific performance standards, such as enhanced chemical resistance or greater load-bearing capacity.

Material Selection

The choice of resin is critical in determining the grating’s performance characteristics. Common resins used in fiberglass grating include:

● Polyester Resin: Cost-effective and resistant to most chemicals, suitable for general industrial use.

● Vinylester Resin: More resistant to corrosive chemicals and high temperatures, making it ideal for harsh environments.

● Epoxy Resin: Offers superior chemical resistance and is often used in highly corrosive settings.

The right resin is chosen based on the intended application and exposure conditions.

Types of Fiberglass Grating

Molded Fiberglass Grating

Molded fiberglass grating is made by layering resin and fiberglass strands within a mold. It offers excellent multi-directional strength, making it perfect for environments where strength is needed in both directions, such as walkways and platforms. Molded grating is commonly used in chemical plants, food processing facilities, and water treatment plants due to its resistance to corrosion.

Key Benefits:

● High impact resistance

● Multi-directional strength

● Corrosion and chemical resistance

Pultruded Fiberglass Grating

Pultruded fiberglass grating is formed by pulling fiberglass through a resin bath and shaping it into bars. This method results in a stronger, more rigid grating system with greater load-bearing capacity. Pultruded grating is used in heavy-duty applications where strength and durability are a priority, such as offshore platforms and large industrial floors.

Key Benefits:

● High load-bearing capacity

● Long-lasting durability

● Ideal for heavy-duty applications

Mesh and Grid Patterns

Fiberglass grating comes in various mesh patterns, such as square, rectangular, and micro-mesh. Each pattern offers unique advantages depending on the application:

● Square Mesh: Offers high strength and is typically used in environments requiring uniform support.

● Micro-Mesh: Has smaller openings, which provide increased strength-to-weight ratios and are ideal for areas that require fine drainage.

These patterns are customizable, allowing for a grating system that meets specific environmental and load requirements.

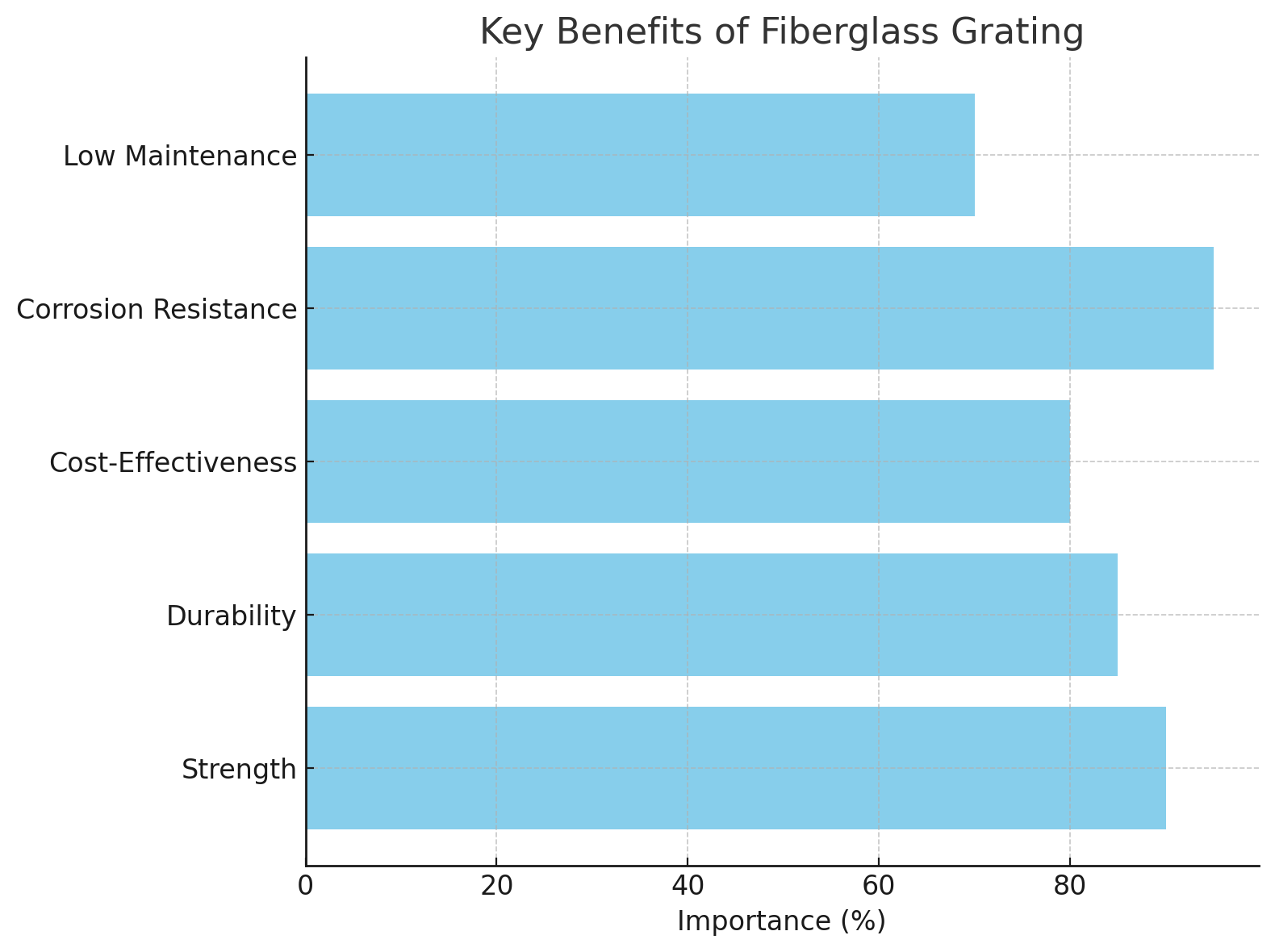

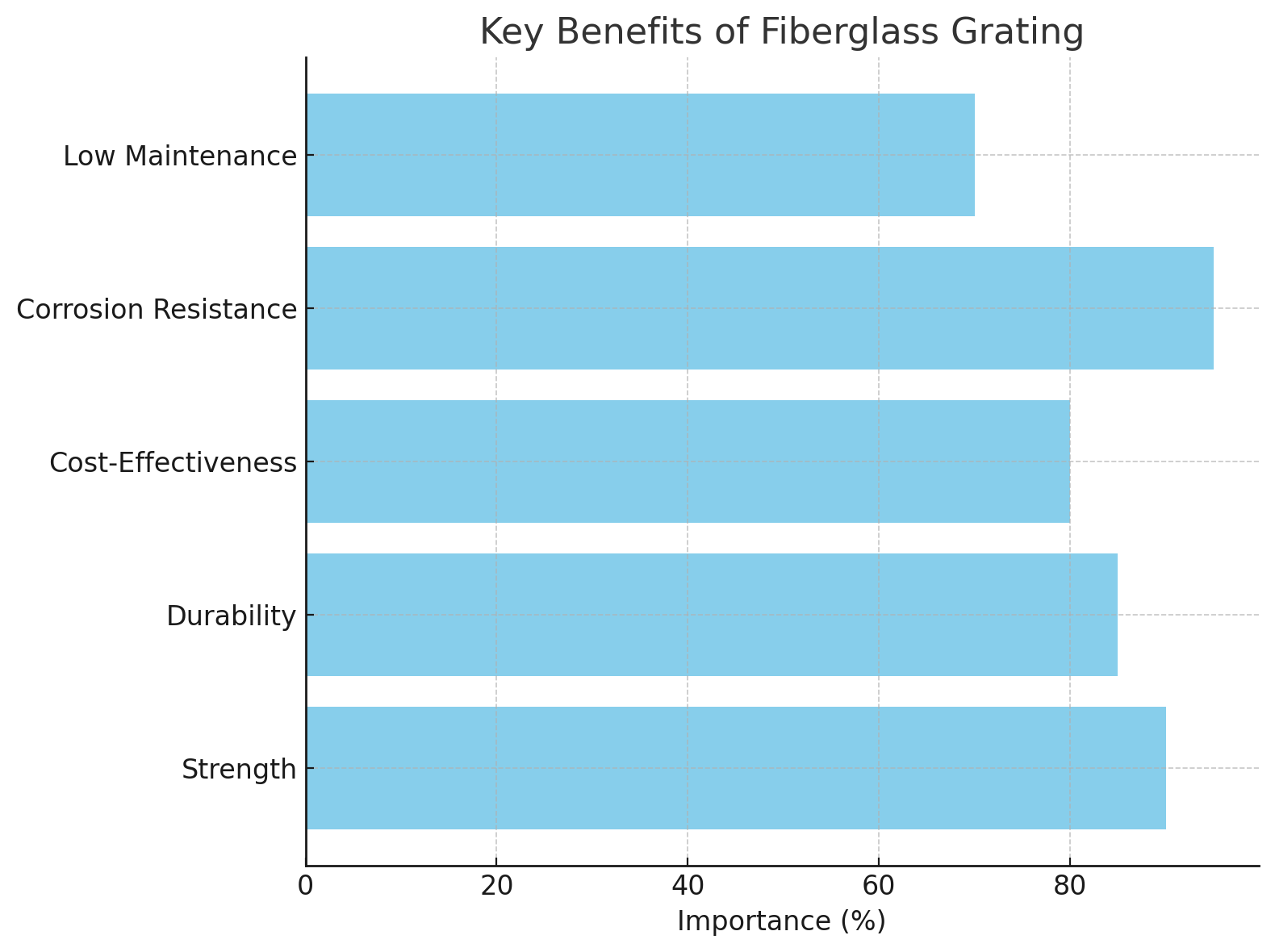

Benefits of Fiberglass Grating

Strength and Durability

Fiberglass grating offers excellent strength-to-weight ratios, making it a strong alternative to heavier materials like steel and aluminum. It performs well in harsh environments, with resistance to corrosion, chemicals, and extreme weather conditions. Unlike steel, it doesn’t rust, and unlike wood, it won’t rot or decay.

Fiberglass grating can withstand heavy loads and impacts without losing structural integrity, making it an ideal choice for industrial applications.

Cost-Effectiveness

Compared to metals like steel, fiberglass grating is a more affordable option for many applications. Its durability and low maintenance requirements mean that you can save money on repairs and replacements over time.

Fiberglass is also lightweight, which reduces transportation costs and installation time.

Low Maintenance

Fiberglass grating is easy to maintain, requiring only occasional cleaning with soap and water. It resists the buildup of dirt, chemicals, and moisture, reducing the need for frequent upkeep. This makes it a low-maintenance option for high-traffic or industrial environments.

Safety Features

Fiberglass grating is designed with safety in mind. Its slip-resistant surface makes it ideal for wet or oily environments, reducing the risk of accidents. Additionally, fiberglass grating is fire-resistant, with some specialized types able to withstand temperatures up to 1700°F, making it a safe option for industries with high-temperature exposure.

Applications of Fiberglass Grating

Industrial Uses

Fiberglass grating is widely used in industries such as:

● Chemical Processing: Its corrosion resistance makes it an excellent choice for environments exposed to harsh chemicals.

● Marine Environments: Fiberglass grating’s resistance to saltwater and other marine elements makes it ideal for use in docks, piers, and offshore platforms.

● Wastewater Treatment: Fiberglass grating resists the corrosive effects of water treatment chemicals, making it a long-lasting solution for water treatment facilities.

Construction and Infrastructure

Fiberglass grating is commonly used in flooring, platforms, walkways, and stair treads in commercial and industrial construction. Its lightweight nature allows for easy installation, while its durability ensures that it can handle high traffic and exposure to harsh elements.

Specialized Industries

Fiberglass grating is also used in more specialized fields such as:

● Offshore Oil and Gas: In environments with high corrosion risks, fiberglass grating provides a reliable solution for platforms and drilling rigs.

● Agricultural Settings: Its durability and resistance to chemicals make fiberglass grating ideal for agricultural settings such as barns and stables.

Comparing Fiberglass Grating to Other Materials

Fiberglass vs. Steel

● Weight: Fiberglass is significantly lighter than steel, making it easier to transport and install.

● Corrosion Resistance: Unlike steel, fiberglass does not rust, making it a better option for corrosive environments.

● Cost: Fiberglass grating is generally more affordable than steel, especially when factoring in its long lifespan and low maintenance.

Fiberglass vs. Plastic and Aluminum

● Durability: Fiberglass outperforms plastic in terms of strength and long-term durability. It is also more resistant to UV degradation than plastic.

● Cost: Fiberglass is generally more cost-effective than aluminum, especially when considering the lower maintenance requirements.

Choosing the Right Material for Your Project

When deciding between fiberglass and other materials, consider factors such as load capacity, exposure to chemicals or harsh weather, and installation requirements. Fiberglass grating is ideal for applications requiring strength, durability, and low maintenance.

Key Considerations When Using Fiberglass Grating

Load Capacity

Ensure that the fiberglass grating you choose can support the intended load for your specific application. Pultruded grating is ideal for heavy-duty applications, while molded grating may suffice for lighter duties.

Environmental Conditions

Select the appropriate resin type for the environmental conditions. For instance, vinylester resin is better suited for environments with high chemical exposure, while polyester is adequate for less demanding conditions.

Customization and Installation

Fiberglass grating is highly customizable and can be cut on-site to fit your specific needs. Its lightweight nature makes installation easier, reducing labor costs.

Conclusion

Fiberglass grating is an innovative material known for its strength, durability, and cost-effectiveness. It offers a reliable alternative to steel and wood, especially in industries requiring corrosion, chemical, and weather resistance. Whether used for platforms, walkways, or stair treads, fiberglass grating provides a versatile and safe solution. With products from Kaiheng, customers benefit from high-quality, long-lasting solutions tailored to meet their specific needs.

FAQ

Q: What is fiberglass grating?

A: Fiberglass grating is a composite material made from fiberglass and resin, offering strength, durability, and corrosion resistance. It's commonly used for industrial flooring, platforms, and walkways.

Q: How is fiberglass grating made?

A: Fiberglass grating is made through two main processes: molding, where resin and fiberglass are layered in molds, and pultrusion, where fiberglass is pulled through resin to form strong, load-bearing bars.

Q: Why is fiberglass grating better than steel?

A: Unlike steel, fiberglass grating is resistant to corrosion, lightweight, and requires minimal maintenance, making it a cost-effective and durable alternative for harsh environments.

Q: Where is fiberglass grating used?

A: Fiberglass grating is used in various industries, including chemical processing, marine environments, wastewater treatment, and construction for flooring, stair treads, and platforms.

Q: How much does fiberglass grating cost?

A: The cost of fiberglass grating depends on factors such as material type, size, and customization. It is generally more affordable than steel in terms of installation and maintenance costs.