Introduction

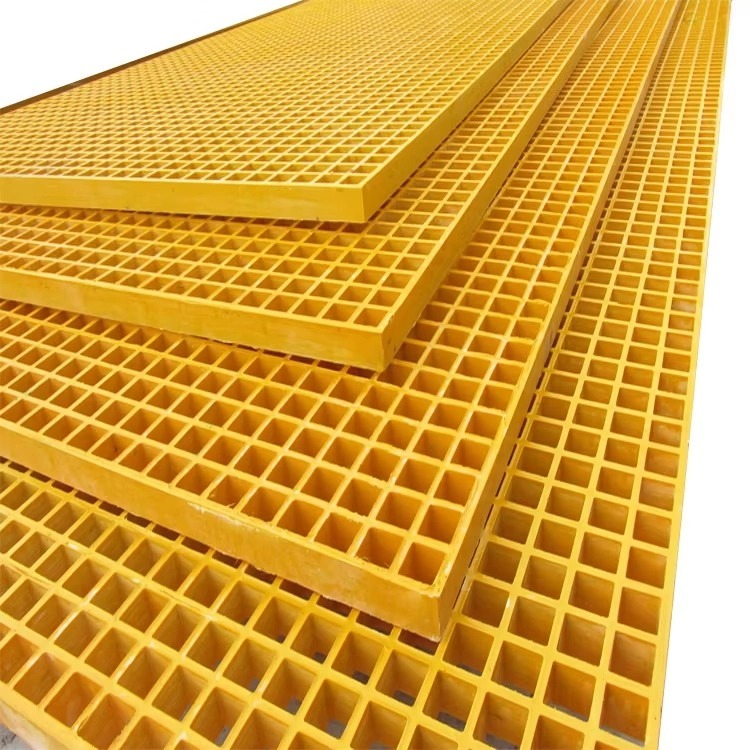

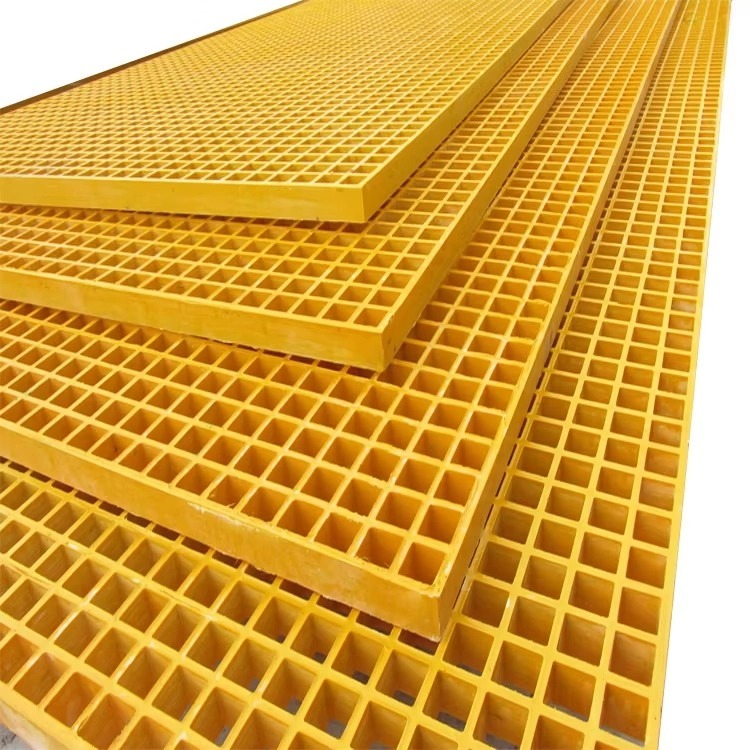

In the world of industrial flooring, platforms, catwalks, and trench covers, choosing the right grating material can significantly impact performance, safety, and maintenance costs. Two of the most widely used materials are fiberglass and steel. While steel has traditionally dominated the market, fiberglass grating—thanks to its modern engineering advantages—is becoming an increasingly popular alternative. But the critical question remains: Is fiberglass grating better than steel grating?

To answer this, we need to explore multiple dimensions, including durability, corrosion resistance, cost-efficiency, weight, ease of installation, safety, and long-term maintenance. This article delves deep into these factors to help you make an informed decision.

Durability and Strength: Can Fiberglass Match Steel?

Material Composition and Structural Integrity

Steel has long been associated with strength and rigidity. It’s made from iron alloyed with carbon, which provides superior load-bearing capabilities. However, fiberglass grating—constructed from glass fibers embedded in a resin matrix—offers surprising strength-to-weight ratios. While steel still outperforms fiberglass in pure tensile strength, fiberglass exhibits flexural strength, which is crucial in dynamic load applications.

More importantly, fiberglass grating maintains its structural integrity in environments where steel might fatigue or corrode. For instance, marine environments or chemical plants expose materials to constant corrosive forces. In these conditions, fiberglass grating does not rust, pit, or deteriorate like steel.

In applications where moderate strength is sufficient but harsh environmental resistance is necessary, fiberglass proves to be more durable in the long term.

Corrosion Resistance: The Hidden Cost of Steel

A Clear Winner in Harsh Environments

One of the most decisive advantages fiberglass has over steel is its excellent corrosion resistance. Steel grating, even if galvanized or stainless, eventually succumbs to moisture, salt, or chemical exposure. Maintenance costs escalate over time due to repainting, recoating, or outright replacement.

On the other hand, fiberglass grating is inherently resistant to:

This resistance makes it ideal for chemical plants, food processing units, offshore platforms, and wastewater treatment facilities.

While steel may be stronger in dry environments, fiberglass wins hands down in corrosive or damp locations, offering a longer service life with minimal maintenance.

Installation and Weight: Lighter Is Often Better

Labor Savings and Structural Load Reduction

Another compelling advantage of fiberglass grating is its lightweight nature. Fiberglass grating is approximately 75% lighter than steel grating, making it significantly easier to transport, handle, and install. In contrast, steel often requires cranes or forklifts for placement.

Fiberglass panels can be cut on-site using simple hand tools—no need for heavy-duty cutting torches or welding, which is often the case with steel. This drastically reduces installation time and labor costs.

Moreover, the reduced weight lessens the structural load on support systems, especially in elevated walkways or platforms. This makes fiberglass grating a cost-effective and time-saving solution for projects with strict installation timelines.

Cost Analysis: Upfront vs. Lifecycle Cost

Is Fiberglass Grating More Expensive?

At first glance, fiberglass grating may appear more expensive than steel grating in terms of initial material cost. However, a deeper financial analysis reveals the true value lies in the total lifecycle cost.

| Factor | Steel Grating | Fiberglass Grating |

| Initial Cost | Lower | Slightly higher |

| Installation Cost | High (equipment needed) | Low (manual tools suffice) |

| Maintenance | Frequent (rust, recoating) | Minimal |

| Replacement Cycle | 5–10 years (in corrosive environments) | 20+ years |

When you factor in savings from reduced labor, zero corrosion-related maintenance, and longer operational life, fiberglass grating becomes more economical over time, especially in aggressive environments.

Safety and Slip Resistance: Which One Protects Workers Better?

Slips, Trips, and Electrical Conductivity

Worker safety is paramount in any industrial setup. Fiberglass grating offers a non-slip surface, often molded with gritted finishes that provide better traction than untreated steel. Even when wet or oily, fiberglass surfaces reduce the chances of slip accidents.

Moreover, fiberglass is non-conductive, making it inherently safer in electrical or explosive atmospheres. Steel, being a conductor, poses significant risk unless grounded and insulated properly.

Steel grating, while durable, can become slippery over time—especially when it oxidizes. This not only increases the risk of workplace accidents but also demands additional safety coatings or treatments.

In high-risk environments, fiberglass grating offers superior safety advantages, making it the preferred choice for OSHA-compliant workspaces.

Application Suitability: Where Does Each Excel?

Matching Grating Material to the Right Job

While fiberglass grating shines in many aspects, steel still has its place. Here’s a quick overview of ideal applications for each:

| Application | Recommended Material |

| Offshore platforms | Fiberglass |

| Food processing | Fiberglass |

| Mining operations | Steel |

| High-temperature zones | Steel |

| Water treatment plants | Fiberglass |

| Manufacturing floors | Depends on load and chemical exposure |

Fiberglass is better suited for wet, corrosive, and electrically sensitive environments, while steel is more appropriate for dry, high-load, or heat-intensive conditions.

FAQ Section: Common Questions About Fiberglass Grating

Can fiberglass grating handle heavy equipment?

Yes, fiberglass grating comes in various load-bearing configurations. Heavy-duty fiberglass panels can support forklift traffic and industrial machinery if properly specified and supported.

Does fiberglass grating fade or break over time?

Fiberglass grating is UV-stabilized and chemically treated to resist degradation. With proper installation, it can last over 20 years with minimal wear.

How do I maintain fiberglass grating?

Maintenance is simple: regular cleaning with water or mild detergents is usually sufficient. No painting, coating, or rust removal is needed.

Is fiberglass environmentally friendly?

Yes, fiberglass requires less energy to manufacture and has a longer lifespan, reducing the frequency of replacements and overall environmental impact.

Conclusion

So, is fiberglass grating better than steel grating? The answer largely depends on your application. If your environment is dry, structurally demanding, and temperature-intense, steel may still be your best bet. However, for most modern industrial, marine, and chemical applications, fiberglass grating outperforms steel in corrosion resistance, weight, installation ease, safety, and long-term cost-efficiency.

Fiberglass grating is not just a replacement—it's a next-generation solution engineered for the demands of the 21st-century industry. Before choosing your grating material, always consider your specific environment, load needs, and maintenance expectations. With fiberglass, you're investing in a material designed for longevity, safety, and savings.