Fiberglass grating has become a cornerstone in modern industrial infrastructure, widely appreciated for its strength, corrosion resistance, and lightweight properties. As industries move away from traditional materials like steel or wood, one critical question consistently arises: How long does fiberglass grating last? In this in-depth article, we will uncover the lifespan of fiberglass grating, examine the factors that influence its durability, and offer maintenance tips to extend its performance.

What Is Fiberglass Grating?

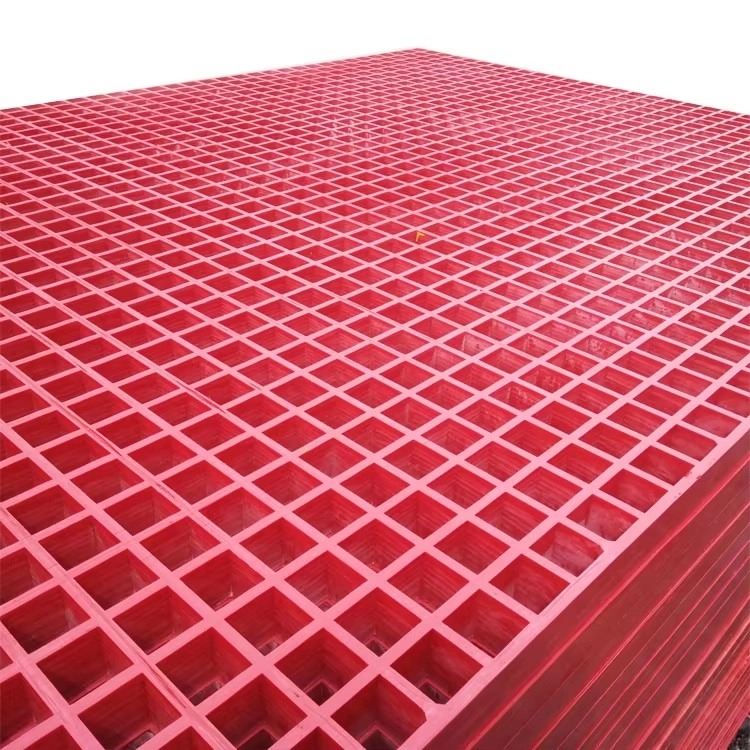

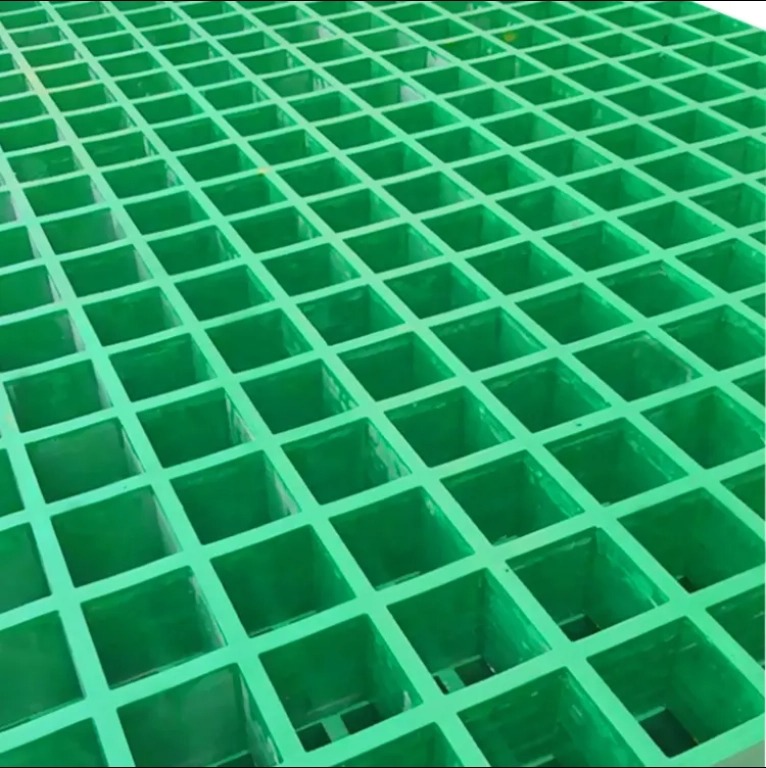

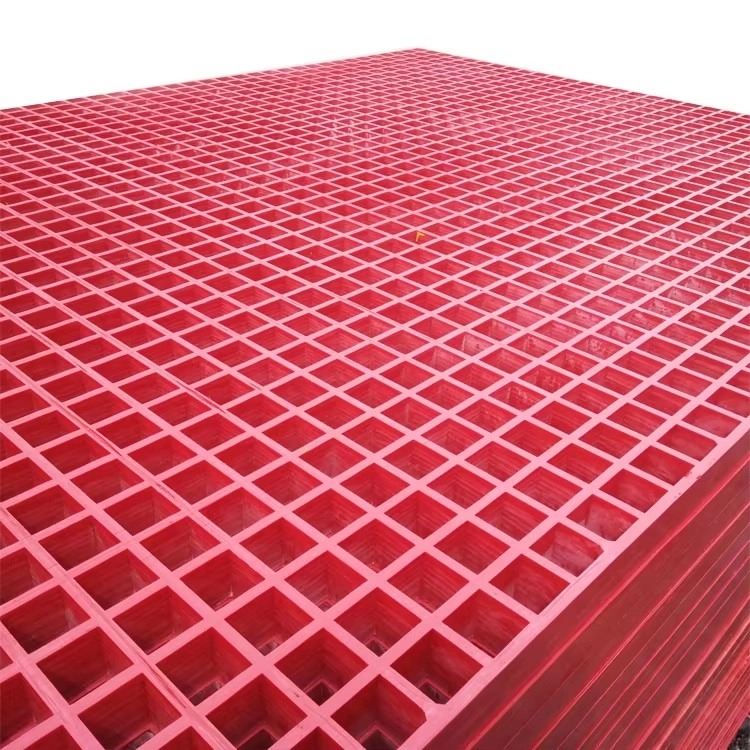

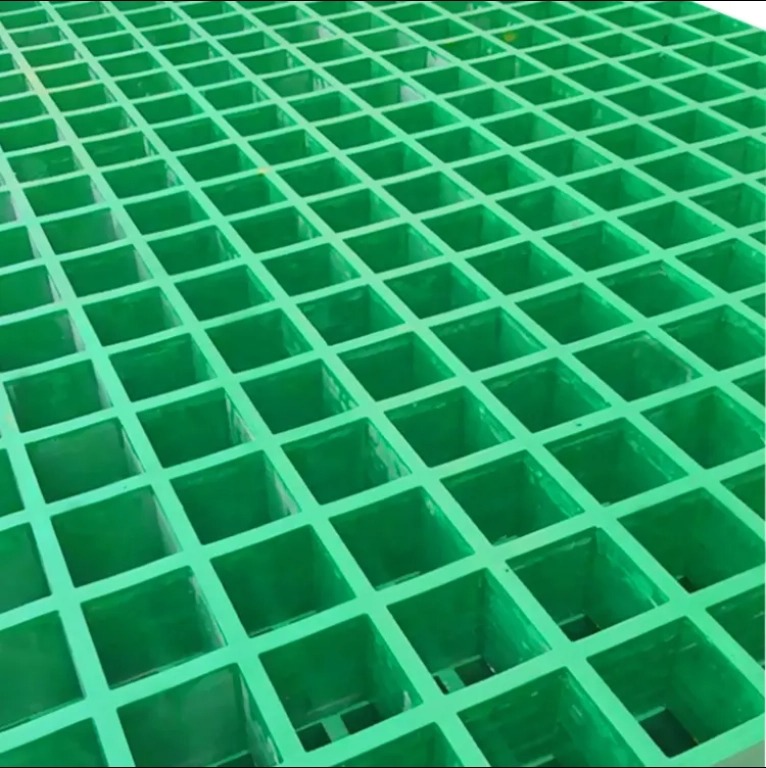

Fiberglass grating is a structural component manufactured using reinforced fiberglass and resin systems. It is commonly available in two forms: molded and pultruded. Molded grating is created by combining fiberglass rovings with resin in a mold to form a solid, one-piece panel, while pultruded grating is produced by pulling fiberglass strands through a resin bath and a heated die to form rigid shapes.

Key Properties of Fiberglass Grating

Corrosion Resistance: One of the most notable advantages, especially in marine, chemical, or wastewater environments.

Non-Conductivity: Ideal for electrical or high-voltage areas.

Lightweight: Easy to transport and install compared to metal grating.

High Strength-to-Weight Ratio: Supports heavy loads without the extra bulk.

These features make fiberglass grating a preferred solution in sectors like oil and gas, food processing, power plants, and more. But durability is where it truly shines.

The Typical Lifespan of Fiberglass Grating

The lifespan of fiberglass grating is heavily influenced by its environment, maintenance routine, load exposure, and the type of resin used in its composition. On average, fiberglass grating can last between 25 to 50 years with proper installation and routine care.

| Condition | Estimated Lifespan |

| Indoor dry environment | 40–50 years |

| Coastal or marine environment | 30–40 years |

| Chemical processing facility | 25–35 years |

| High-traffic pedestrian use | 20–30 years |

What sets fiberglass grating apart from steel or aluminum is its resistance to rust, corrosion, and warping, which can significantly reduce replacement frequency.

What Factors Affect the Lifespan of Fiberglass Grating?

Several critical factors influence how long fiberglass grating will serve effectively. Let’s explore them in detail:

1. Environmental Conditions

Harsh exposure to chemicals, UV rays, saltwater, or high humidity can degrade certain resins more quickly. However, fiberglass grating made with vinyl ester resin often performs well in aggressive environments.

2. Load Bearing and Usage

Continuous heavy load or dynamic impact may wear down the structural integrity of the grating over time. In industrial applications where forklifts or heavy equipment are involved, pultruded grating is often recommended for its superior load-bearing capacity.

3. Installation Quality

Proper installation ensures that the grating bears weight evenly. Misalignment, poor anchoring, or improper cutouts can concentrate stress on specific areas, shortening its service life.

4. Maintenance Frequency

While fiberglass grating is low-maintenance, periodic inspection, especially in corrosive environments, helps prevent minor damages from becoming structural failures.

Is Fiberglass Grating Worth the Investment?

Absolutely. When considering long-term performance, fiberglass grating offers a superior return on investment. Although the initial cost might be higher than traditional grating, its minimal maintenance needs, corrosion resistance, and longevity significantly reduce lifecycle costs.

Cost Comparison Over 30 Years (Estimates)

| Material | Initial Cost | Maintenance Cost | Replacement Frequency | Total 30-Year Cost |

| Steel Grating | Medium | High | Every 10–15 years | High |

| Aluminum | High | Medium | Every 15–20 years | Medium |

| Fiberglass | Medium | Low | Every 30–50 years | Low |

When downtime and labor for replacement are considered, fiberglass often outpaces the alternatives in financial efficiency.

How to Extend the Lifespan of Fiberglass Grating

You can maximize the life of your fiberglass grating by adopting a few smart practices:

1. Choose the Right Resin

Depending on your environment, select a resin type that suits your needs:

Isophthalic polyester for general-purpose use

Vinyl ester for chemical resistance

Phenolic for fire resistance and low smoke

2. Perform Regular Inspections

Look for signs of:

Cracks

Fiber bloom

Surface delamination

Loose fasteners

Early detection can prevent costly failures down the road.

3. Keep It Clean

Regular cleaning using mild detergent and water helps preserve the grating’s non-slip surface and prevents dirt buildup that may harbor corrosive elements.

4. Avoid Excessive Heat Exposure

Although fiberglass can handle moderate heat, continuous exposure to high temperatures can degrade its resin matrix.

Frequently Asked Questions About Fiberglass Grating

Q1: Can fiberglass grating be used outdoors?

Yes, fiberglass grating is UV stabilized and corrosion-resistant, making it suitable for outdoor use, especially in marine, coastal, or rooftop applications.

Q2: Does fiberglass grating rust over time?

No, fiberglass is non-metallic and completely resistant to rust and corrosion, unlike steel or iron grates.

Q3: Is fiberglass grating fire-resistant?

Certain types of fiberglass grating, especially those made with phenolic resin, offer excellent fire resistance and meet fire safety standards.

Q4: How can you tell when fiberglass grating needs replacement?

Signs include visible cracks, surface deterioration, soft spots under pressure, and noticeable reduction in load-bearing performance.

Q5: Can fiberglass grating be repaired?

Minor surface damage can often be patched, but extensive structural compromise may require full replacement.

Conclusion

Fiberglass grating is more than just an alternative to metal—it’s a long-term solution for businesses seeking durability, safety, and low maintenance. With proper care and the right environmental fit, fiberglass grating can easily last 30 to 50 years, providing excellent value and reliability. For environments that demand resilience and safety, fiberglass grating stands the test of time.