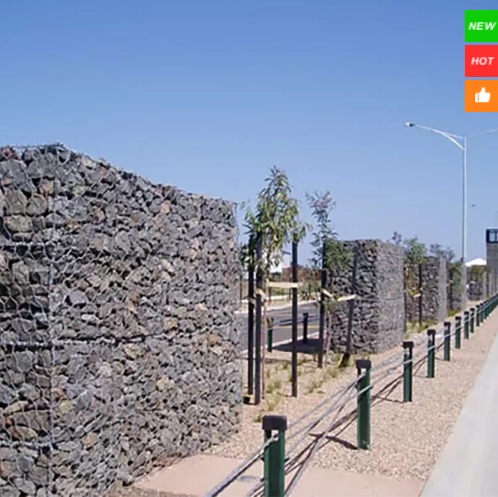

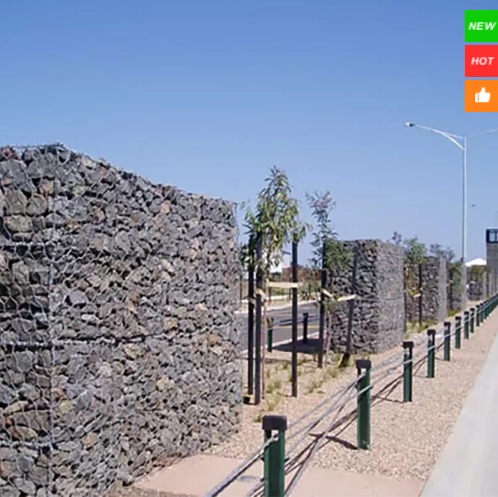

Have you ever wondered how to tackle erosion or create durable retaining walls? Gabion boxes and gabion nets offer a robust solution. These wire mesh cages filled with rocks provide stability and aesthetic appeal. In this post, you'll learn the importance of proper gabion installation and a step-by-step guide to ensure a successful project.

Preparing the Site for Gabion Installation

Site Assessment and Preparation

Before installing gabion boxes, start by assessing the site thoroughly. Check the ground for stability and remove any loose debris or vegetation. The surface must be solid enough to support the gabion structure without sinking or shifting. If needed, excavate the area according to the project’s design specifications. Proper drainage should also be considered to avoid water pooling, which might weaken the gabion base over time.

Engineer Specifications and Requirements

Follow all engineer-provided specifications carefully. These include dimensions, materials, and installation methods tailored for your project. Specifications might dictate the type of rockfill, mesh size, or the thickness of the wire mesh. Adhering to these ensures the gabion structure’s durability and performance. If unsure, consult the engineer to clarify any requirements before proceeding.

Surface Leveling and Quality Assurance

Level the surface precisely to match the design grade. Use tools like laser levels or spirit levels for accuracy. A flat, even base helps the gabion boxes sit correctly and prevents uneven pressure that could cause bulging or distortion. Quality assurance checks during this step are crucial—recheck the surface after leveling to confirm it meets the required tolerances. A well-prepared foundation sets the stage for a strong, long-lasting gabion installation.

Understanding Gabion Materials

Types of Gabion Boxes and Nets

Gabion boxes come in various types, mainly distinguished by their size, mesh structure, and coating. Typically, they are rectangular wire mesh cages made from galvanized steel wire, often coated with PVC for added corrosion resistance. The mesh size usually ranges around 8 cm by 10 cm for boxes, while gabion mattresses have slightly smaller mesh openings, about 6 cm by 8 cm. The wire diameter for boxes is commonly 2.7 mm, providing strength and durability, whereas mattresses use thinner wire around 2.2 mm.

Different gabion types suit different projects. For example, small gabions are ideal for landscaping or small retaining walls, while larger gabions handle heavy-duty applications like riverbank protection or highway embankments. The choice depends on the structural requirements and site conditions.

Material Specifications and Standards

The wire mesh must meet strict quality standards to ensure gabions last long and perform well. Galvanized steel provides rust resistance, and the PVC coating adds extra protection against weather and chemicals. The wire mesh should be woven in a double-twisted hexagonal pattern, which prevents unraveling if one wire breaks.

Engineers specify the mesh size, wire diameter, and coating thickness based on the project’s needs. For example, a thicker wire or heavier coating might be required in aggressive environments like coastal areas. Adhering to these specifications ensures gabions resist corrosion, maintain shape, and support the rockfill properly.

Selecting the Right Rocks for Filling

Choosing the right rocks is crucial for gabion stability and appearance. The rocks must be clean, solid, and non-friable, meaning they do not easily break down. Quarried rock is preferred, meeting engineer specifications for size and quality.

Typically, rock size must be larger than the mesh openings to prevent stones from falling out. The bulk specific gravity should be at least 2.6, with low absorption (maximum 2%) and soundness to resist weathering and frost. Flat-faced, larger stones are best for the exposed faces to create a neat, stable appearance.

When filling gabions, large rocks go on the visible side, hand-placed for an attractive finish. Smaller stones fill the interior, often machine-loaded to speed up construction. This method minimizes voids and ensures structural integrity.

Assembling Gabion Boxes

Unpacking and Unfolding Gabion Boxes

When the gabion boxes arrive on site, they come folded flat and packed in bundles to save space. Start by unloading them carefully, ideally using a forklift or suitable lifting equipment. Place the bundles on a hard, flat surface to prepare for unfolding.

Open the bundles and gently unfold each gabion box. You’ll see the panels folded inward. Lay the box flat first, then rotate the front, back, ends, and diaphragms into vertical positions. This forms the box shape needed for installation. Make sure the panels stand upright and are not bent or damaged.

Lifting Panels into Position

Once the gabion box is unfolded, lift the side panels, end panels, and internal diaphragms into their final vertical positions. This step shapes the cage and prepares it for filling. It’s important to handle the panels carefully to avoid deforming the wire mesh.

If the gabion units are large, you may need mechanical assistance or multiple workers to lift and hold panels in place. For smaller gabions, this can usually be done by hand. Position the gabion boxes on the prepared site surface according to your project layout, ensuring they align with the design lines and levels.

Securing Panels with Lacing Wire

After positioning, secure the panels together using lacing wire. This wire is woven through the mesh openings, binding adjoining panels tightly. The lacing should be continuous along all vertical and horizontal joints. Pass the wire through each mesh opening, wrapping it around the selvedge wires on both panels, then twist it twice to secure.

Start lacing at one corner and work your way along the joint, pulling the wire tight to create a firm connection. At the start and end points, wrap the wire around the panel wires three times for extra strength.

For longer gabion runs, lace sections no longer than about 1 meter to maintain tension and stability. If available, you can also use helical wire connectors or C-clips to join panels; they speed up assembly and provide strong joints. Helicals are twisted into the mesh, while C-clips require a pneumatic closing tool and are usually reserved for larger projects.

Once all vertical and horizontal joints are laced, attach the lid panel loosely, ready for filling. The lid will be firmly secured after the gabion is filled and settled.

Filling and Stabilizing Gabion Boxes

Machine vs Hand Filling

Filling gabions can be done by machine or by hand, depending on the project size and site conditions. Machine filling is faster and suitable for large gabion units or long runs. It involves using excavators or loaders to dump rockfill into the cages. However, machine filling may create voids or uneven distribution if not done carefully.

Hand filling is slower but allows for better control, especially on the exposed faces of gabions. Large, flat-faced rocks should be hand-placed on the visible sides to create a neat, stable appearance. Smaller stones can fill the interior, often loaded by machine or hand. This combination ensures both speed and quality.

Minimizing Voids and Ensuring Stability

Voids inside the gabion reduce its structural integrity. To minimize voids, fill the gabion in layers, compacting each layer by hand or using equipment like vibrators or tampers. Slightly overfill the gabion to allow for settlement later.

Encourage settlement by walking on the rockfill or using mechanical compaction. Adjust the surface after settlement to ensure it is level and smooth. Avoid filling one cell completely before moving to the next unless internal bracing is installed, as this can cause distortion.

Installing Cross-Ties for Support

For gabions taller than 500 mm, install cross-ties made from HDPE braid or wire at vertical intervals of 250 to 400 mm. These ties connect opposite panels inside the gabion, preventing bulging and maintaining shape during and after filling.

Cross-ties improve the gabion’s stability and finish quality. They should be securely fastened around mesh intersections on opposite panels. If the gabion is very large or deep, additional internal bracing may be required to maintain structural integrity.

Securing and Lacing Gabion Structures

Closing and Lacing Gabion Tops

After filling the gabion boxes, the next step is closing and lacing the tops securely. Place the lid panel over the filled cage, ensuring it fits snugly without gaps. Use lacing wire to fasten the lid to the sides and diaphragms. The wire should be woven continuously through the mesh openings along all edges, pulling tight to hold the lid firmly in place. Proper lacing prevents rock spillage and maintains the gabion’s shape during use.

Make sure to lace all the horizontal and vertical joints on the lid, just as done on the sides. Start at one corner and work your way around, wrapping the wire around the selvedge wires at the edges for extra strength. For longer gabion runs, keep lacing sections no longer than one meter to maintain tension. If you have multiple gabions connected, lace the lids so they tie adjacent units together, enhancing overall stability.

Ensuring Structural Integrity

The structural integrity of gabion assemblies depends heavily on tight, consistent lacing and proper closure. Loose or poorly secured tops can lead to rock displacement, bulging, or deformation of the gabion. To avoid this, check all laced joints for tightness after closing the lid. If any section feels loose, re-lace or tighten the wire.

Additionally, internal bracing such as cross-ties should be installed before closing the lid, especially for gabions taller than 500 mm. These ties reduce bulging by connecting opposite panels inside the cage, distributing pressure evenly. Properly installed cross-ties combined with secure lacing ensure the gabion remains rigid and durable over time.

Temporary external supports like timber or scaffolding tubes can be used during filling and lacing to prevent bulging or distortion. Remove these supports only after the gabion is fully secured and stable.

Using Helicals and C Clips

Besides traditional lacing wire, helicals and C clips offer efficient alternatives for joining gabion panels. Helicals are spiral wires twisted through the mesh to bind panels quickly. They require only one helical per joint and are turned at the ends to prevent loosening. Helicals speed up assembly and provide strong, flexible connections.

C clips are metal rings closed with a pneumatic tool, mainly used in large or commercial projects. They must be spaced every other mesh opening along joints for proper strength. Though requiring special equipment, C clips deliver very secure connections and save time on big installations.

Choosing between lacing wire, helicals, or C clips depends on project size, available tools, and desired speed. For smaller jobs, lacing wire is reliable and cost-effective. For large-scale or repetitive installations, helicals or C clips can improve efficiency without compromising quality.

Tip: Always ensure the gabion lid is tightly laced and all joints are secure before finishing the installation to maintain long-term stability and prevent rock loss.

Common Challenges and Solutions

Dealing with Settlement and Bulging

Settlement and bulging are common issues during gabion installation. Settlement happens when the rockfill compresses or shifts after filling, causing the gabion surface to sink or become uneven. To minimize this, slightly overfill each gabion and encourage settlement by walking on the rockfill or using light compaction tools. Overfilling allows the rocks to settle naturally without leaving voids.

Bulging occurs when the wire mesh panels bow outward due to internal pressure from the rockfill. This is especially common in taller gabions. To prevent bulging, install cross-ties or internal bracing at vertical intervals of 250 to 400 mm. These ties connect opposite panels inside the gabion, distributing pressure evenly and maintaining shape. If bulging starts to appear, check that ties are tight and properly positioned. Temporary external supports like wooden planks or scaffolding tubes can also help hold the shape during filling.

Adjusting for Surface Irregularities

Uneven or irregular surfaces beneath gabions can cause instability and distortion. Before placing gabions, ensure the site is leveled and compacted according to engineer specifications. If slight irregularities remain, adjust by adding a thin layer of compacted granular material or sand to create a uniform base.

When laying gabions on slopes or uneven ground, stagger the units and use smaller gabions or gabion mattresses to conform better to the terrain. Make sure each gabion is securely laced to adjacent units to distribute loads and prevent shifting. If the surface irregularities are significant, consider excavation or a reinforced foundation to provide a stable base.

Ensuring Longevity and Durability

Gabion structures exposed to harsh environments require extra care to last long. Use PVC-coated wire mesh to resist corrosion, especially in coastal or chemically aggressive areas. Follow engineer specifications for wire diameter, mesh size, and coating thickness to ensure durability.

Regularly inspect gabion installations for signs of damage, wire breakage, or rock loss. Promptly repair any damaged sections by replacing broken wires or relacing panels. Proper drainage around the gabion also extends its life by preventing water buildup that could weaken the base or cause erosion.

In addition, select high-quality, non-friable rockfill that withstands weathering and frost. Avoid using rocks smaller than the mesh openings to prevent loss through the mesh. Proper filling techniques, including hand placement of face rocks and machine loading of interior, help maintain the gabion’s structural integrity over time.

Conclusion

Proper gabion installation involves site assessment, adherence to engineer specifications, and meticulous preparation. Ensuring stability through surface leveling, quality assurance, and secure lacing is crucial. Gabions require the right materials and careful filling techniques to prevent structural issues like settlement and bulging. For successful projects, always verify rock size, use cross-ties, and choose quality materials. KaiHeng offers durable gabion solutions that withstand harsh environments, providing long-term value and reliability.KaiHeng

FAQ

Q: What is a Gabion box and how is it used?

A: A Gabion box is a rectangular wire mesh cage filled with rocks, used for erosion control, retaining walls, and landscaping. Its design allows for flexibility and durability in various environmental conditions.

Q: How do I ensure proper installation of Gabion nets?

A: Ensure proper installation by preparing the site thoroughly, following engineer specifications, leveling the surface accurately, and securely lacing the Gabion nets to prevent structural issues.

Q: Why are Gabion boxes preferred for certain projects?

A: Gabion boxes are preferred due to their strength, flexibility, and ability to blend with natural surroundings. They offer effective erosion control and are cost-efficient compared to concrete structures.

Q: What are the benefits of using Gabion nets?

A: Gabion nets provide excellent drainage, reduce erosion, and are environmentally friendly. They adapt to ground movement, ensuring long-term stability and reducing maintenance costs.

Q: How can I troubleshoot common issues with Gabion installations?

A: Address settlement by overfilling gabions, prevent bulging with cross-ties, and adjust for surface irregularities by leveling and compacting the site. Regular inspections and maintenance ensure longevity.